When you have to consider buying a new machine for your company, the evaluations need to be done are many. You can start to evaluate strenghts and weaknesses of the instrument. You can ask to yourself whether the investment will cover the costs and will brings profits.

Why the laser system, especially the galvanometric laser, is the least risky choice?

The answer is very simple: it is, thanks to its versatility!

The galvanometric laser can work on different material types. For example, you have to produce a large order for a customer that asks for 10.000 leather uppers. Which is the tool you can reuse for a new process? Maybe on different materials and to produce different results? The answer is: the laser system.

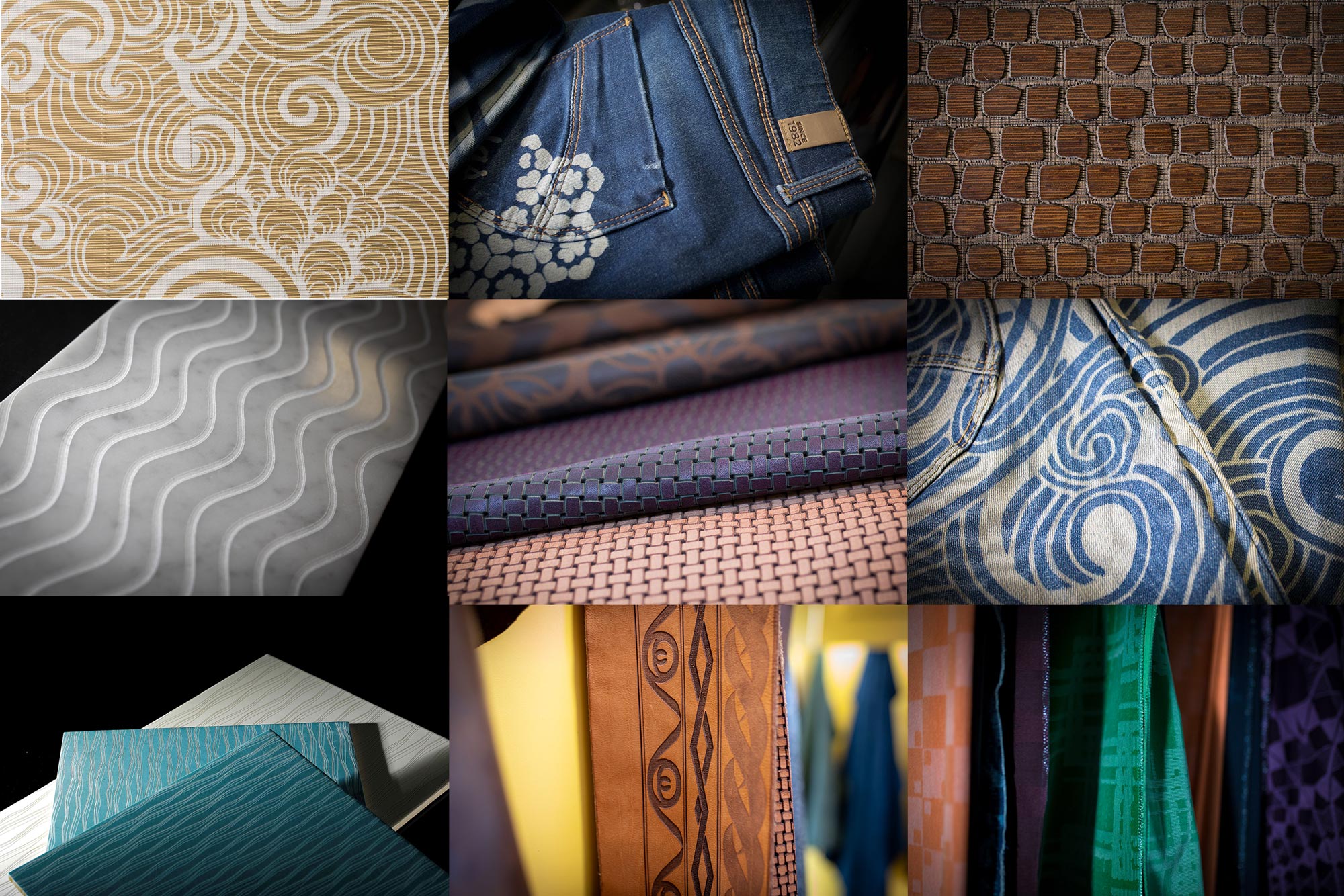

The laser system is suitable for processing different types of materials and surfaces, like wood, marble, fabrics, glass, etc. The fact of not being a highly specific machine is its strong point. Being able to be used in different sectors and for different uses, one quality above all makes it functional: versatility.

The satisfaction of having a laser machine in the company lies precisely in its ability to work different material types and to change its use according to the needs.

This capacity is even more amplified in the galvanometric machines with the Ot-las radiofrequency CO2 laser. This is because the speed of the galvo head allows to reduce drastically the times of customization in a process.

We manage to import files of any extension (using DXF, AI, JPG, BMP) thanks to our Corel Draw graphic motor. Be it customizing, engraving, marking or cutting, all power and speed values are entered directly on the Smart Draw docket of the machine contained directly in Corel Draw.

The laser is one of the greenest technologies on the market. It doesn’t require a big amount of energy and it doesn’t produce pollution.

To learn more about the Ot-las laser features, watch the video about the new laser BX solution.