Maximum Power

850 W

Maximum Area

500×500 mm

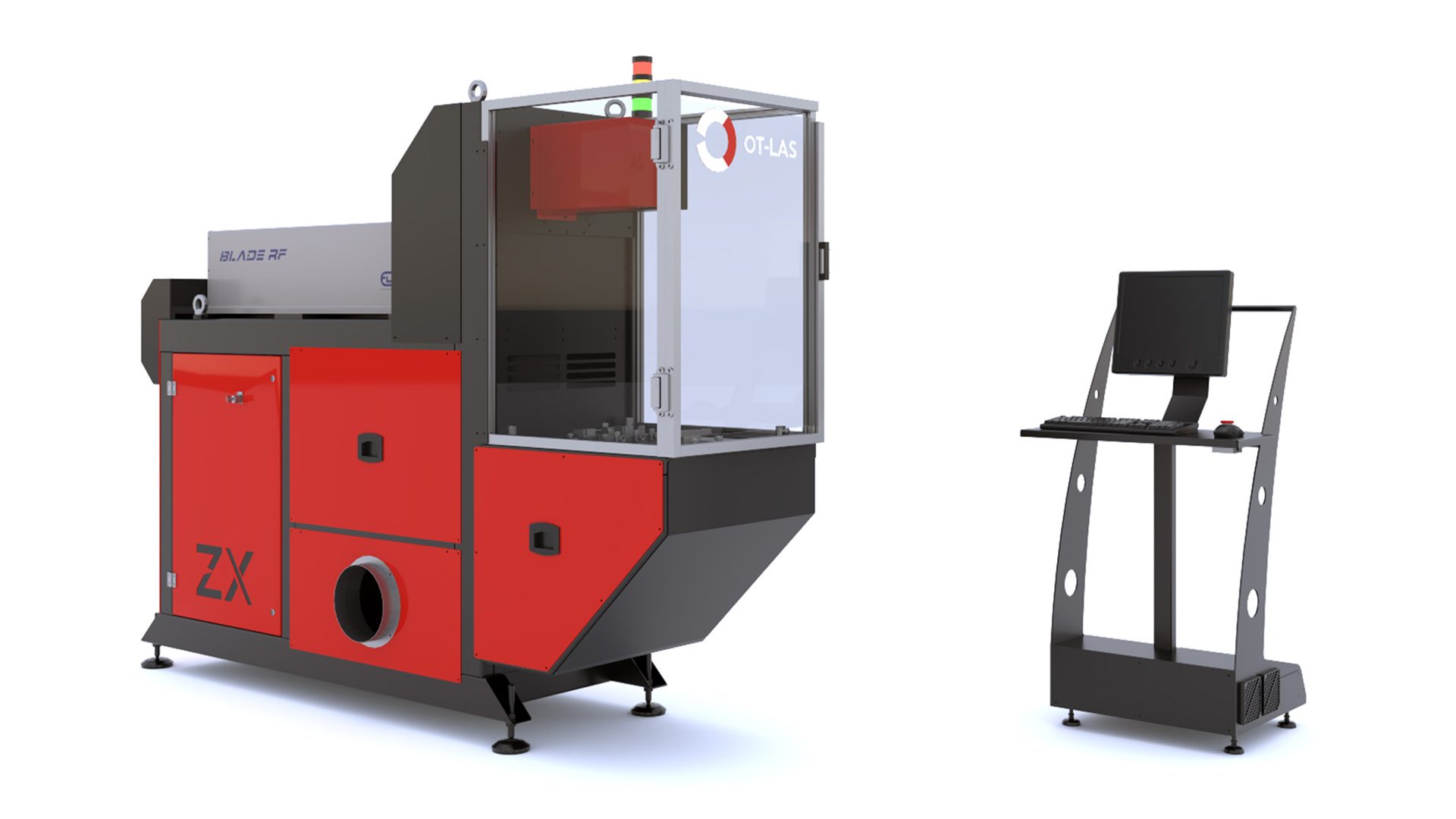

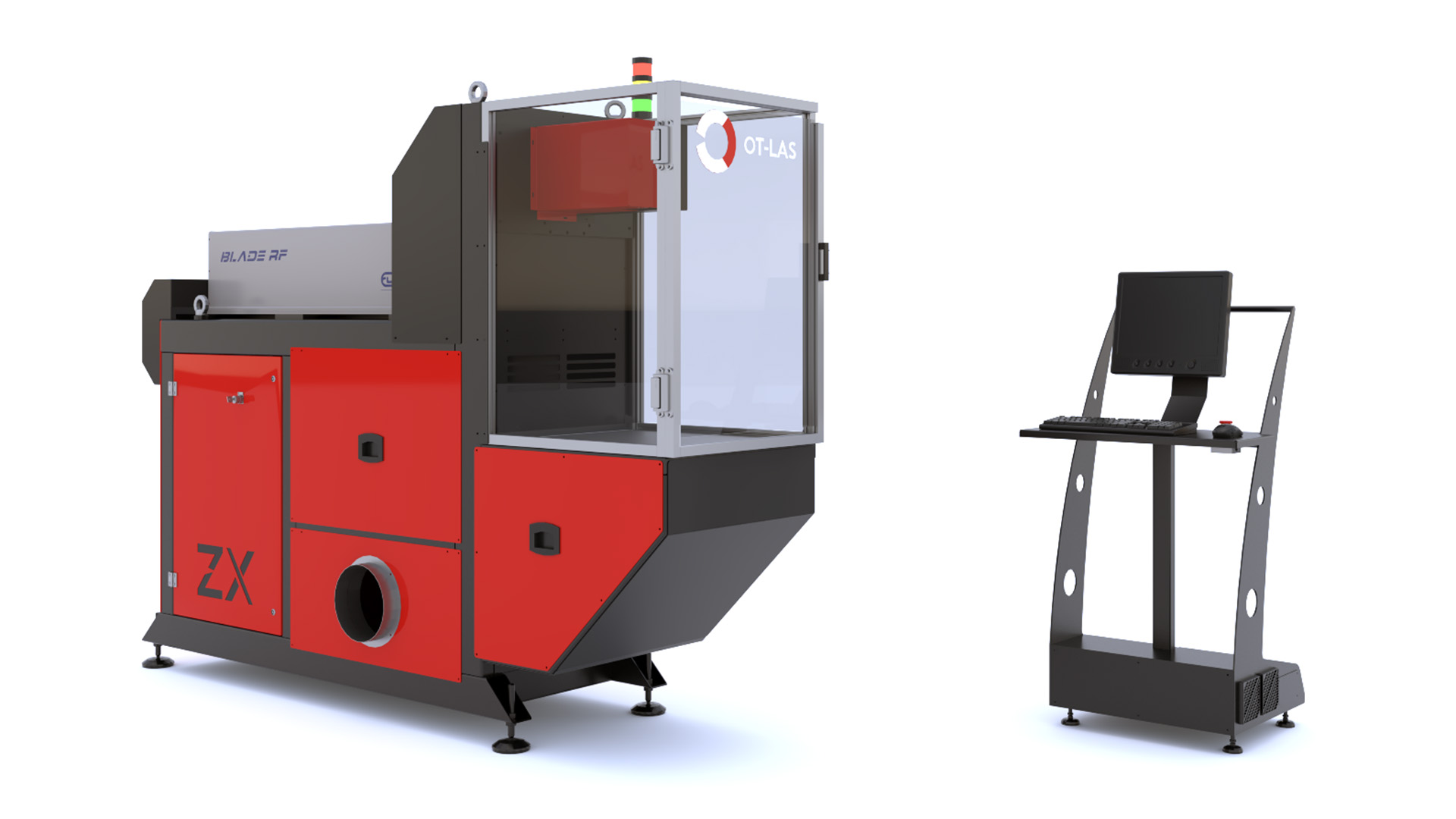

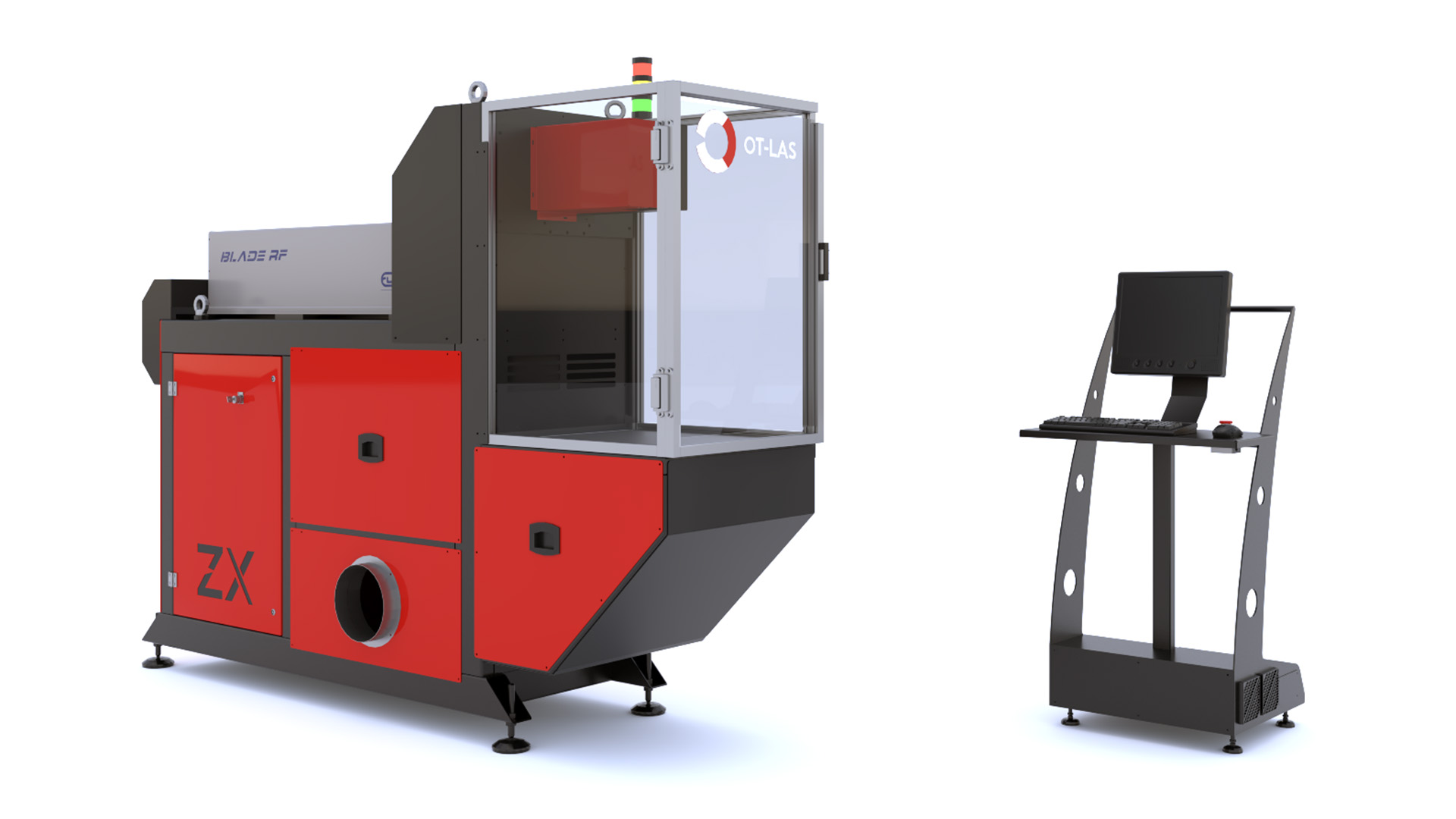

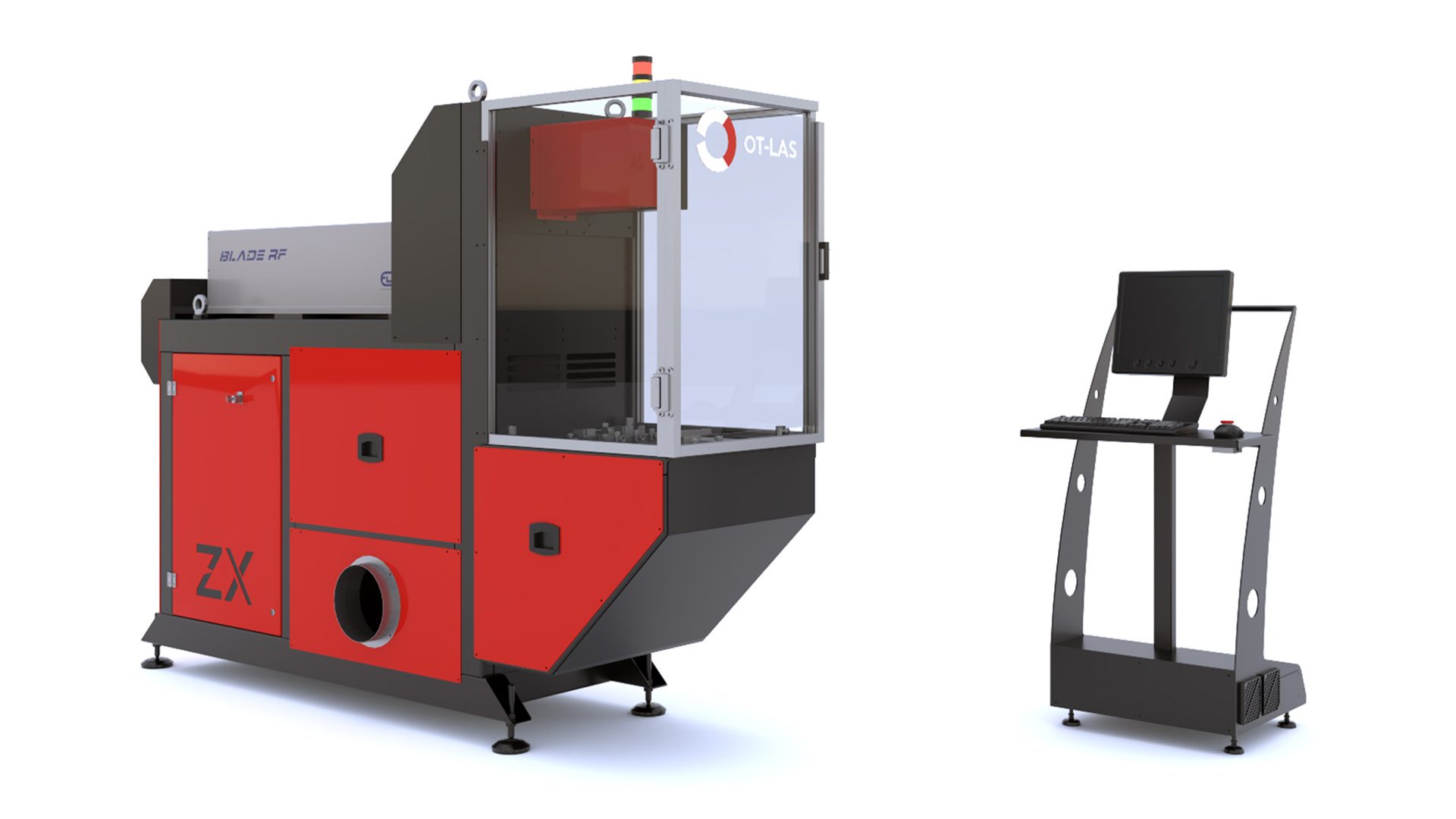

ZX, small laser marking and cutting for immediate needs

Designed and implemented based on the market’s requests, ZX is OT-LAS laser solution conceived for those companies that want to start without renouncing to cut, half-cut and marking of paper, textile, leather and wood.

ZX is a simple solution yet suitable for multiple sectors, from gadget to fashion.

ZX can process the following materials:

- Textile

- Leather

- Wood

- Acrylic

- Paper

Advantages of the ZX laser machine

The ZX laser machine built on a solid and compact mechanic structure particularly suitable for smaller processing environments.

It can manage powers up to 850 Watt and it is one of the most compact and flexible solutions existing on the market to date.

The ZX highlights:

- Equipped with graphic and operating software and Corel Draw graphic engine.

- One of the most flexible solutions on the market.

- Its three-axis optical system guarantees perfect focusing in all points of the working table.

Technical characteristics

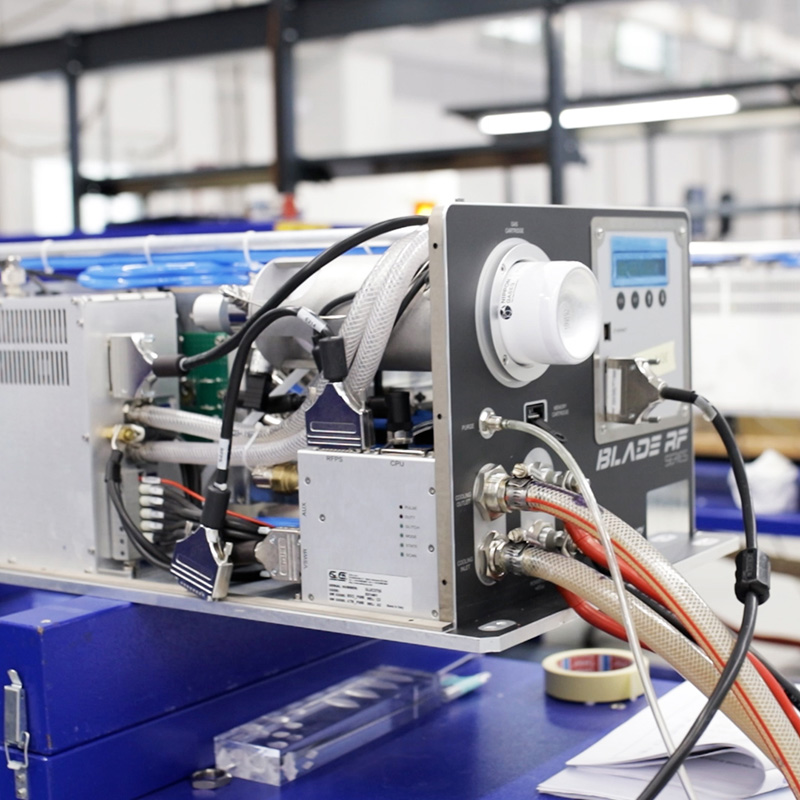

| Blade RF | 303 (Sealed off) | 333 | 555 | 777 | 888 (Semi sealed) |

| Rated power (W) | 300 | 350 | 550 | 750 | 850 |

| Electric consumption | 9 | 9 | 10 | 12 | 13 |

| Useful marking area (mm) | 500×500 – Rated Spot 0.5 mm (standard) 300×300 – Rated Spot 0.3 mm (on demand) | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 Hz refrigerator: 400 3F+T ±10% – 50 Hz | ||||

303 (Sealed off) 333 555 777 888 (Semi sealed)

300 350 550 750 850

9 9 10 12 13

500×500 – Nominal spot 0.5 mm (standard)

300×300 – Nominal spot 0.3 mm (on request)

machine: 400 3F+T ±10%

50 Hz

chiller: 400 3F+T ±10%

50 Hz

Accessories and hardware for ZX

Insole table

Automatic table for insoles with tilting system.

Software for ZX

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.

The SmartTrack software is designed to carry out insole excavation. Excavation profiles and cutting of eyelets are projected to insoles, opportunely positioned on valid reference systems for each size and shape.