Maximum Power

1500 W

Maximum Area

700×700 mm

BX Multiaxes, the 3D laser cutting and marking system

BX multiaxes perfectly applies to all types of materials, except for PVC, if referred to the system rotary axis.

The BX system guarantees a uniform engraving depth over the entire decorated surface, starting from the original 3D file. Extremely varied decorations can be made with multiple patterns on the material to be processed.

BX Multiaxes can process the following materials:

- Wood

- Plastic

Advantages of the BX Multiaxes laser machine

The BX multiaxes solution, which can be configured starting from BX system, is ideal to decorate 3D surfaces, starting from the original shape and managing the drawing sequences.

The BX Multiaxes highlights:

- Designed to change the system configuration for multifunctional decoration purposes.

- Traditional clamping is not necessary.

- Integrity of the parts before and after laser processing.

- Easiness of loading and unloading the parts from the system.

- A number of configuration possibilities due to laser source power and optical head resolution.

Technical characteristics

Together with the software, the axis handling system contributes to the creation of the object surface decoration. The software allows modelling and dividing the 3D file on the surface of the object to be processed.

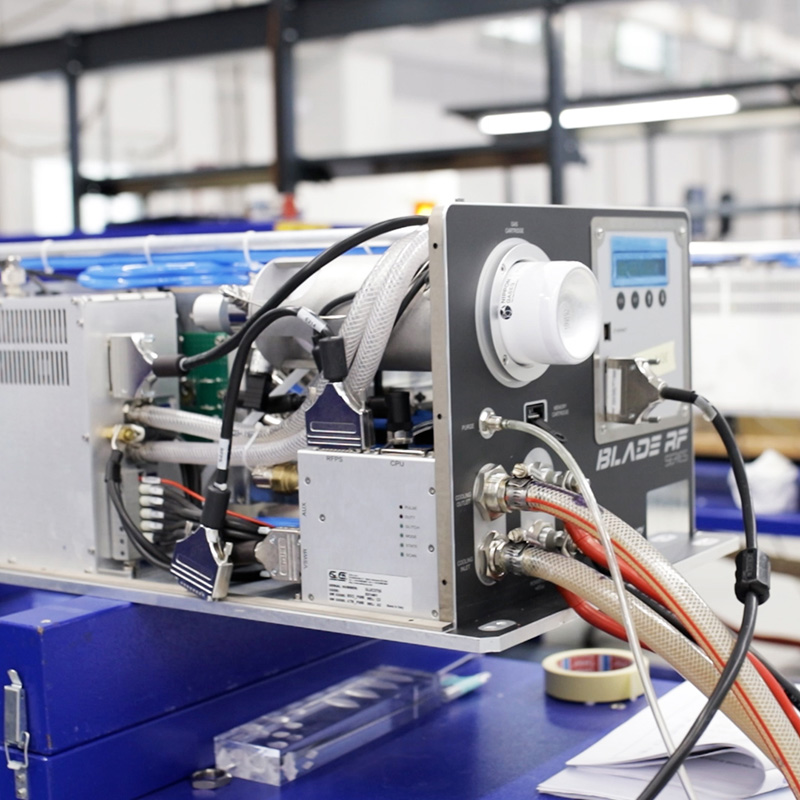

| Blade RF | 555 | 777 | 888 | 1222 | 1555 |

| Rated power (W) | 550 | 750 | 850 | 1200 | 1500 |

| Electric consumption (kW) | 10 | 12 | 13 | 22 | 23 |

| Useful marking area (mm) | from 500×500 to 700×700 – Rated Spot from 0.25mm to 0.35mm | ||||

| Galvanometric polar scanning optical head | Optical aperture70mm | ||||

| BX selectable configuration | The system can be configured to BX (processing on standard grill system), user-selectable | ||||

| Electric power supply (VAC) | machine: 400 3F+T ±10% – 50 Hz refrigerator: 400 3F+T ±10% – 50 Hz | ||||

Accessories and hardware for BX Multiaxes

Automatic moving table

Double-station insole table

Insole table with tilting system. The table movement can be either automatic or manual.

Software for BX Multiaxes

A graphic and operating software with specific Corel Draw graphic engine for the realization of files and for the entire system functioning. For each work, it is possible to assign geometric parameters, processing parameters and set any drawing repetitions or compositions, in case the system is equipped with automatic table.

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.

Software for the recognition of plan surfaces edges. Due to this application, laser processing will be optimized based on the surface requested. Smart Trim is combined with the vision system.

The SmartTrack software is designed to carry out insole excavation. Excavation profiles and cutting of eyelets are projected to insoles, opportunely positioned on valid reference systems for each size and shape.