RX, the 3D laser cutting kit

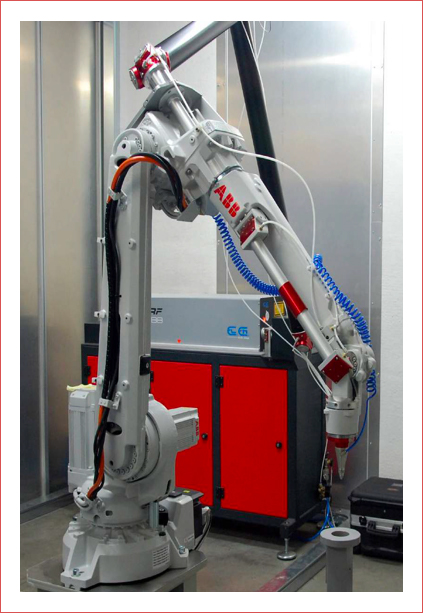

RX is a high-precision high-flexibility laser cutting kit; optical connection with articulated arm allows optimizing robot and laser in specific applications.

It is realized by coupling a robot with a CO2 laser source, through a 7-mirror articulated optical arm, which guarantees perfect transfer of laser power to the cutting head, mounted on the wrist of the robot itself. The system is available for the dressing of ABB and FANUC robots.

It is the system chosen by the most important companies of the sector for cutting the cold-storage rooms.

ABB IRB 2600 ID 200

FANUC ARC Mate 120iD/12L

Configuration of the RX kit

RX has different configuration possibilities that make use of ABB and FANUC robots with 1.45 m and 2.0 m of boom extension, each of which can be coupled with El.En sources from 88W up to 1200W, all with RF technologies.

Two possible kinds of configuration: with cutting head and galvanometric scanning head. The last one is very interesting because it allows reducing cutting times, since the robot is used only to get nearer the cutting area. In this case, cutting is carried out taking advantage of the movement of the mirrors placed on the scanning head, which is much higher than the mechanic displacement of the robot.

The RX highlights:

- Reduced maintenance (8 hours per year)

- Limited machine downtime for maintenance

- Booth does not need soundproofing

- Simplified assembly

- No mechanic contact with tools

- High execution speed

- High efficiency

- No need for additional processing

- Limited operating costs

The RX kit with focusing head

The RX system is equipped with focusing head (5” or 7” lens), specific for thermoformed products in ABS, HDPS, carbon fibre, fiberglass, Kevlar, plastic in general. Available for ABB IRB 2600 ID 200 and FANUC ARC Mate 120iC/12L models.

Applications:

- Car interior

- Dashboards

- Bumpers

- Blown plastic components

Components:

- Laser beam guidance system

- Cutting head

- EL.EN laser sources series RF Blade

- ABB and FANUC robots

RX kit with scanning head

Specific for thermoformed products with a thickness lower than 4 – 3 mm, its main application is refrigerator/freezer inner liner. Available for ABB IRB 2600 ID 200 and FANUC ARC Mate 120iC/12L models.

Applications:

- Car interior

- Dashboards

- Abs

- Polystyrene Hdps

- Plexiglass

- Plastic

- Fiberglass

- Carbon fibre

- Kevlar

Components:

- Sistema di guida del fascio laser

- 1735 scanning head

- EL.EN laser sources series RF Blade

- ABB and FANUC robots

Technical characteristics

RX is a product designed for the finishing, by 3D cutting, of plastic components, thermoformed, stamped or blown products, and composite materials. Cutting is carried out without any burr or carbonization traces, even on materials such as carpets and similar.

Compared to other methods, the RX laser robot has a high competitivity on the finishing of car interior components, or refrigerator and freezer internal parts, bikers’ helmets.

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Useful marking area (mm) | Fix | ||||

| Electric Power Supply (VAC) | 380 3F+N | ||||

Accessories and hardware for RX

H35 scanning head

Galvanometric scanning system internally developed by OT-LAS with 35mm optical aperture.

Cutting head

Focusing head with 5″ and 7.5″ lenses.

Distance sensor

Distance sensor to keep the correct focusing during cutting.

Software for RX

A graphic and operating software with specific Corel Draw graphic engine for the realization of files and for the entire system functioning. For each work, it is possible to assign geometric parameters, processing parameters and set any drawing repetitions or compositions, in case the system is equipped with automatic table.

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.