Cutting, drilling and laser marking of polyester are increasingly common processes in companies that handle this material, as they are precise, efficient and sustainable. The technological innovation of CO2 laser machines perfectly responds to the wide range of applications of this synthetic fiber, from film production to technical fabrics. Here are the advantages of laser technology for cutting polyester that allow you to keep up with the growing market demand.

What is polyester?

Polyester is one of the most widely used synthetic fibres in the world, used in many sectors from fashion to industrial production. This oil-derived material is particularly resistant, elastic and lightweight, able to dry quickly. All these features make it ideal for sports and technical clothing as well as fabrics for interior design and outdoor furniture. Polyester is also widely used in the production of plastic films, industrial products and components, thanks to the low cost of the fiber and its easy maintenance.

How does laser processing of polyester work?

Thanks to its chemical structure, polyester is very suitable for various laser processing such as cutting, perforating and marking. Laser cutting of polyester provides clean and precise edges, eliminating the risk of a “fraying” effect and imperfections typical of traditional cutting methods. The wavelength of the CO2 laser beam is easily absorbed by the material, which does not suffer damage or deterioration of mechanical properties during processing. The laser’s unrivalled precision also enables high-quality cuts to be made even in the most complex profiles. The main laser processing of polyester includes:

Laser cutting of polyester

In laser cutting of polyester a concentrated laser beam melts or vaporizes the material along a predetermined cutting line. This process is controlled by advanced software which allows to program and produce elaborate drawings with a precision more than millimetric. By not putting pressure on the material, the CO2 laser prevents deformation and minimizes production waste. The laser is also able to automatically seal polyester edges during cutting, preventing fabric fraying, a common problem in manual or mechanical cutting.

Laser marking and engraving of polyester

In laser marking, the material is removed to a certain depth, which is regulated by the control of the laser power. The effect ranges from lighter marking to contrast effects to achieve a particular aesthetic, tactile and visual performance on fabrics and polyester products.

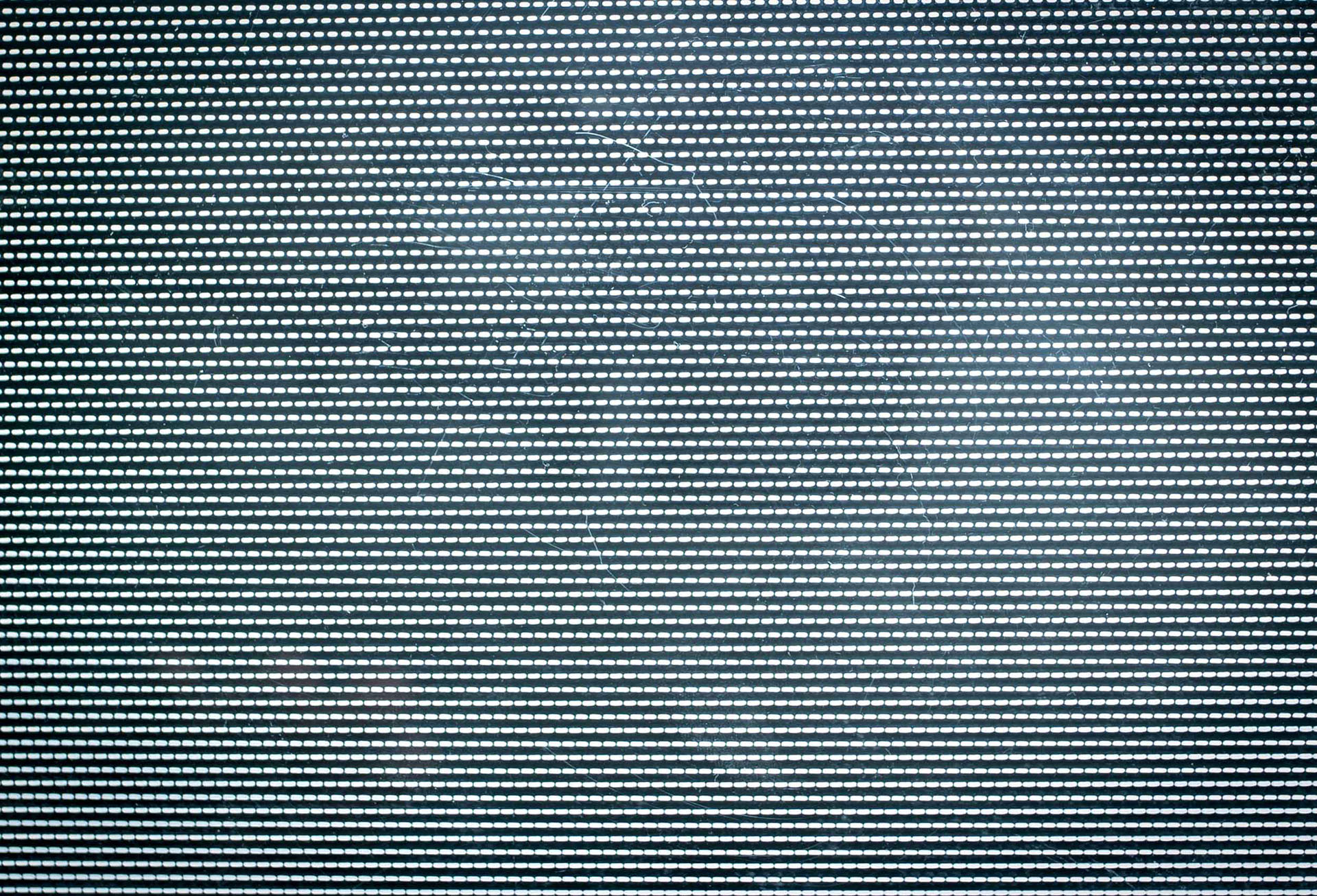

Laser microperforation of polyester

Another highly prized laser processing, especially in the production of technical fabrics, is microperforation. Thanks to the laser it is possible to obtain holes of different sizes with perfectly smooth edges, customized patterns and maximum replicability. Laser microperforation is therefore very useful for effects with decorative or breathable function.

All applications of laser cutting of polyester

Laser cutting and marking of polyester is used in a wide range of industries, given the spread of this synthetic fiber and the excellence of the laser performance in its processing. The main areas covered are:

- Textile industry: laser cutting is widely used to make technical and sports clothing in polyester. It also allows you to create decorations and details in clothing items, such as brands, logos and complex motifs.

- Graphics and design: laser marking of polyester allows to make custom prints or engravings on fabrics, with the possibility of working on curved or irregular surfaces.

- Packaging industry: polyester films are widely used in packaging, and laser cutting allows you to create tailor-made packaging with precise finishes and no burrs.

- Industrial technical components: Polyester is used to produce a number of technical components such as belts and insulators which require high precision cutting. The laser meets this requirement by ensuring accurate cuts even on thin thicknesses.

- Decorations and gadgets: thanks to laser marking, you can create personalized promotional gadgets, such as keychains, plaques or accessories in polyester, adding logos or graphics with durable and accurate engravings.

Recycling polyester with laser cutting

One of the main advantages of laser cutting in polyester processing is its sustainability. Polyester is a recyclable material and more and more companies are looking for ways to recover and reuse this material, helping to reduce plastic waste. In this research, laser cutting plays an important role due to its precision and efficiency. By making precise cuts without producing significant waste or contaminating the material, the laser allows to recover even small portions of fabric or plastic and work them again. This maximises the use of materials and allows new products to be created within the circular economy. The CO2 laser is a sustainable technology in itself, thanks to its low energy consumption compared to other cutting technologies and the processing without solvents and chemical inks.

The advantages of OT-LAS laser machines for cutting polyester

The laser machines made in Italy by OT-LAS are internationally recognized for their quality, reliability and technological innovation. Designed to meet the precision and sustainability demands of today’s market, they offer cutting-edge performance for processing this material.

The main advantages of an OT-LAS laser machine include:

- Maximum precision and speed, to ensure extreme attention to detail in cutting and marking a delicate material such as polyester, while optimizing production times.

- Advanced technology made in Italy, the result of a constant research and development process to offer machines with ever more efficient performance and automated control software.

- One-stop shop without intermediaries to guarantee you maximum reliability and a personalized support before, during and after the sale.

- Flexibility of use thanks to versatile machines for the processing of different materials and the possibility of customized configurations to meet every need of use.

- Exceptional variety of effects and customizations, thanks to the precision of laser technology and programming through dedicated software.

- Possibility to decorate, mark and cut fabrics at the same time with unique and exclusive effects.

Discover the polyester laser machine tailored to your company or contact us for information.