Interior design is living a new era thanks to the endless possibilities introduced by laser engraving with 3D effect. This advanced technology allows to transform traditional materials into innovative surfaces, combining aesthetics and functionality in the service of increasingly customized environments. The CO2 laser systems allows to obtain details of incredible precision and unique and sophisticated textures, opening new paths for creativity and experimentation.

The advantages of galvanometric laser for interior design

The rapid success of galvanometric lasers in interior design allows designers and architects to express new ideas and develop revolutionary concepts. Whether it is decorative surfaces, functional elements or furniture solutions, laser engraving is today an essential resource to meet the increasingly demanding demands of the sector. The speed and high precision of the laser make it possible to enhance environments with exclusive aesthetic solutions but also to optimize their livability and safety. At the same time, the use of laser machines also brings considerable advantages for companies which can, for example:

- Create complex engravings, textures, scripts and graphics in a very short time.

- Operate on different materials, such as wood, glass, metal, plastic, marble and ceramic, with a single technology.

- Ensure consistent workmanship, even on large surfaces.

- Minimize waste and damage to materials, reducing both procurement costs and storage and disposal costs.

- To respond promptly to changes in the market, thanks to the flexibility of the processes and the infinite possible applications.

- Make the process more sustainable, by producing less waste and working without using ink or other chemicals.

Another great advantage of the galvanometric laser is its ability to adapt to projects of different sizes, from the small detail of a decorative object to the customization of entire panels for walls or floors. This means that both the prototyping phases and large-scale production can be optimised.

For interior design, it also means creating decorative and functional elements that meet high standards of quality and efficiency, improving both the appearance and practicality of environments. In addition, the versatility of the laser ensures the faithful reproduction of every detail, allowing to create exclusive textures, patterns and motifs.

Innovative material effects: 3D made with laser

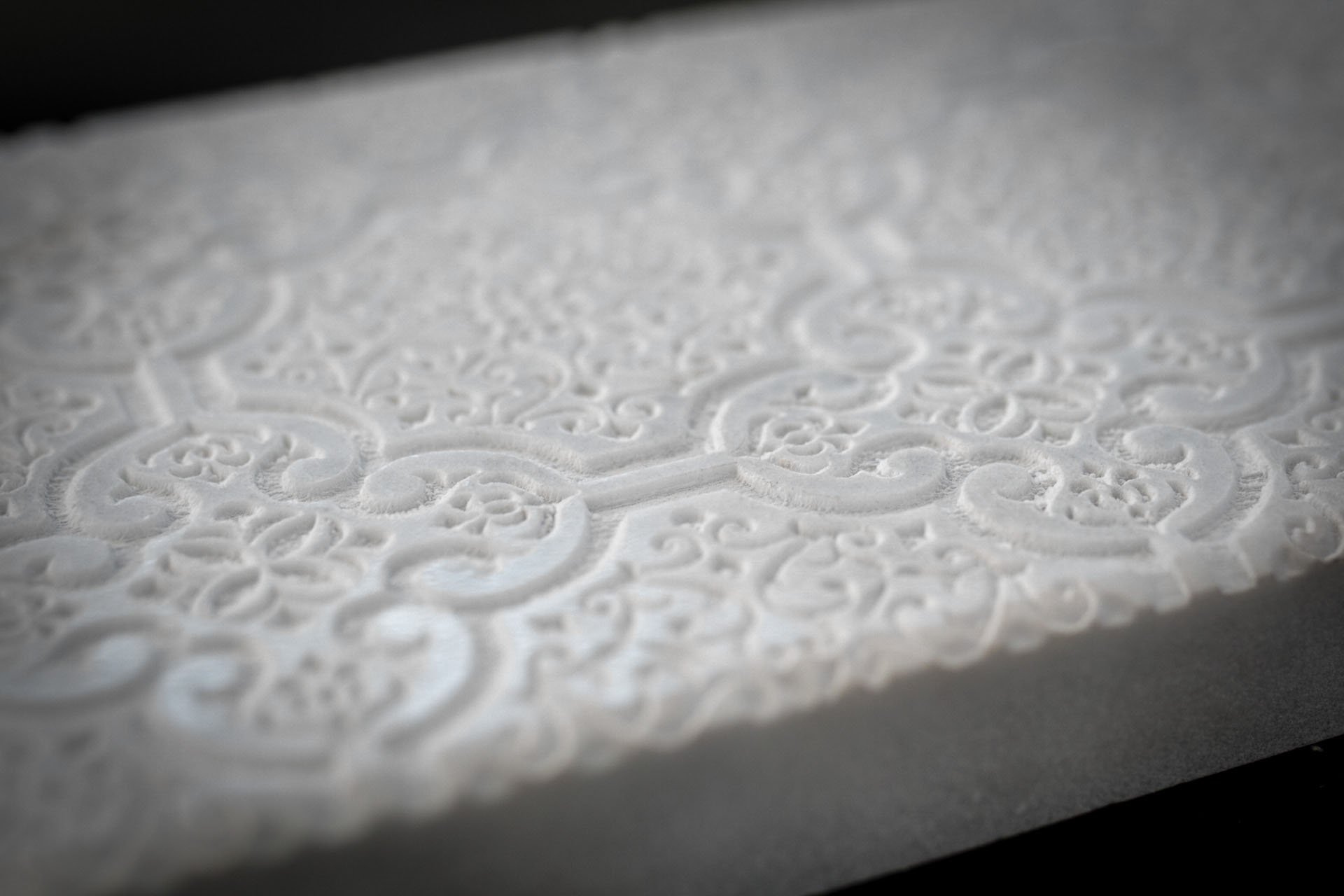

One of the most popular applications of laser in interior design is the ability to create three-dimensional material effects adding depth and dynamism to surfaces. These effects are achieved by modulating the laser power and engraving speed to create detailed patterns and textures. The result is refined workmanship that meets different design styles leaving space for innovative solutions. The trend effects in interior design include:

- Natural textures, such as the reproduction of wood veins, stone or fabrics that recall the original beauty of raw materials.

- Geometric effects that meet the needs of modern and minimalist design, playing with lights and shadows or contrasts of surfaces.

- Artistic reliefs, obtained with deep engravings that transform flat surfaces into true works of art.

- Combined effects, such as overlays of textures and reliefs to create multisensory surfaces with a profound aesthetic impact.

This kind of freedom allows you to customize each design project, making it unique and distinctive according to the customer’s requirements. The effects obtained with 3D lasers can also have a practical function in specific applications of interior design, to increase efficiency and hospitality in public and private environments.

The applications of laser processing: aesthetics and functionality

Laser engraving and marking offers solutions to give comfort and habitability to environments with results previously unattainable with other technologies. One example is:

Non-slip flooring

Laser engraving allows you to create non-slip surfaces on materials such as stone, ceramic or wood. These engravings increase the friction of the ground with the shoes increasing safety without compromising the design. Non-slip floors are required in the construction of some interiors and mandatory in environments where people walk barefoot.

Thanks to the precision of the laser, you can create custom non-slip patterns that combine functionality and style, seamlessly integrating with the desired aesthetic. This solution is therefore ideal for floors in hotels, spas or public spaces, ensuring optimal grip and a refined appearance. Compared to other techniques for making non-slip floors, such as the use of chemical treatments and standard coatings, laser offers greater sustainability, customization and durability.

QR code engraving

Another rapidly growing application of laser in interior design is the creation of QR codes for information and traceability purposes. For example, you can integrate QR codes into decorative panels or furniture, offering additional information without compromising aesthetics. This application is particularly useful in commercial or museum contexts, where QR codes can provide details on the materials used, production techniques or history of furniture items.

Microperforation of acoustic panels

The micro-drilling of wood panels is among the applications that have made from apristrada to laser technology in interior design. This type of processing allows the sound-absorbing properties of acoustic panels to be optimised for soundproofing. Thanks to the CO2 laser, it is possible to create holes of precise dimensions, densities and spacings, improving the acoustic quality of the environments with micro-points imperceptible to touch and sight.

Sound-absorbing panels are indispensable in environments such as theatres, auditoriums, offices and homes where noise reduction is essential to ensure comfort and functionality. In addition, the micro-perforation with CO2 laser allows to customize panels with decorative patterns, transforming them into real design elements.

Laser engraving of walls and panelling

Walls and panelling can be transformed into elegant decorative elements thanks to the infinite possibilities of the laser. Deep engravings, geometric patterns or artistic drawings give the rooms an exclusive character, with customized solutions and a remarkable aesthetic impact. For example, you can decorate the walls of a hotel with motifs that recall the theme of the structure, or create boiserie with three-dimensional textures that add depth and charm to prestigious interiors.

Furniture and design objects

From custom-made furniture to decorative objects, 3D laser engraving has increased exponentially the possibilities of realization for interiors of domestic and commercial environments. Tables, chairs, lamps and other accessories can be enriched with textures, patterns and logos engraved by laser, for a truly unique design.

This technology allows to create small pieces of furniture, making each piece an exclusive work of design. Laser engraving also allows for the creation of prototypes or limited editions, responding to the demands of an increasingly customised market.

Lasers to optimize lighting

CO2 lasers have also been used in recent years to create surfaces that optimize the diffusion of light. With the growing interest in Light Design solutions to separate rooms functionally even without walls, the precision and flexibility of the laser has proved essential. For example, it is possible to cut and micro-drill translucent materials to obtain light and shadow effects, improving the atmosphere of the rooms. An application particularly suitable for lamps, ceiling and backlit panels, to transform a simple light source into a unique design element.

Laser machines for interior design: the Made in Italy of OT-LAS

OT-LAS is an Italian company with over 40 years of experience in the design and production of CO2 laser machines for interior design. Thanks to cutting-edge technologies, the result of constant research and development, OT-LAS offers innovative solutions that combine reliability, performance and design. The OT-LAS laser machines enable:

- To produce very high precision machining on a wide range of materials, such as wood, natural stone, glass, plastic and fabric.

- Work on large formats, with exclusive laser systems configured to customer needs.

- Customize each project with maximum versatility, thanks to the possibility of creating unique effects and high-profile textures, meeting the needs of designers and architects.

- Reduce waste and operating costs, thanks to efficient and ecological processes, starting from the reduced energy consumption and high quality processing, without mechanical contact and without use of chemical solvents.

- Receive dedicated assistance both in the design phase and in the after-sales, thanks to the proprietary technology and the internal supply chain.

With the technology of OT-LAS, the interior design sector can explore new creative possibilities, offering original solutions that allow companies and professionals to achieve excellent results. Thanks to the advantages offered by CO2 laser and the innovation of OT-LAS Made in Italy machines, designers and architects have a powerful tool at their disposal to transform any proposal into a high profile project.