Choosing the suitable laser machine for your processing purposes is essential to increase productivity and amortize the investment with long-term saving. Many laser systems are now marketed that differ considerably in price, quality and performances. The success of laser for processing and engraving materials pushes every year new companies to get this precious instrument. Yet how can you find your way around in the choice of the best laser machine?

Which aspects need to be considered in the choice of a laser system

Before getting a laser machine, it is advisable to carefully assess the use you intend to do of it, and the production process you want to integrate the system into. Some types of lasers are more suitable for certain materials and cutting/engraving thicknesses. Moreover, size, performances and assistance can differ a lot from one company to the other. Here are the aspects to be considered to make an accurate choice:

Type of laser based on the processing

The first aspect to be considered is what type of laser is more suitable for your company production. Laser technology implies a thermal processing, and it is divided into CO2 laser systems and laser fibre machines.

Materials to be laser-engraved

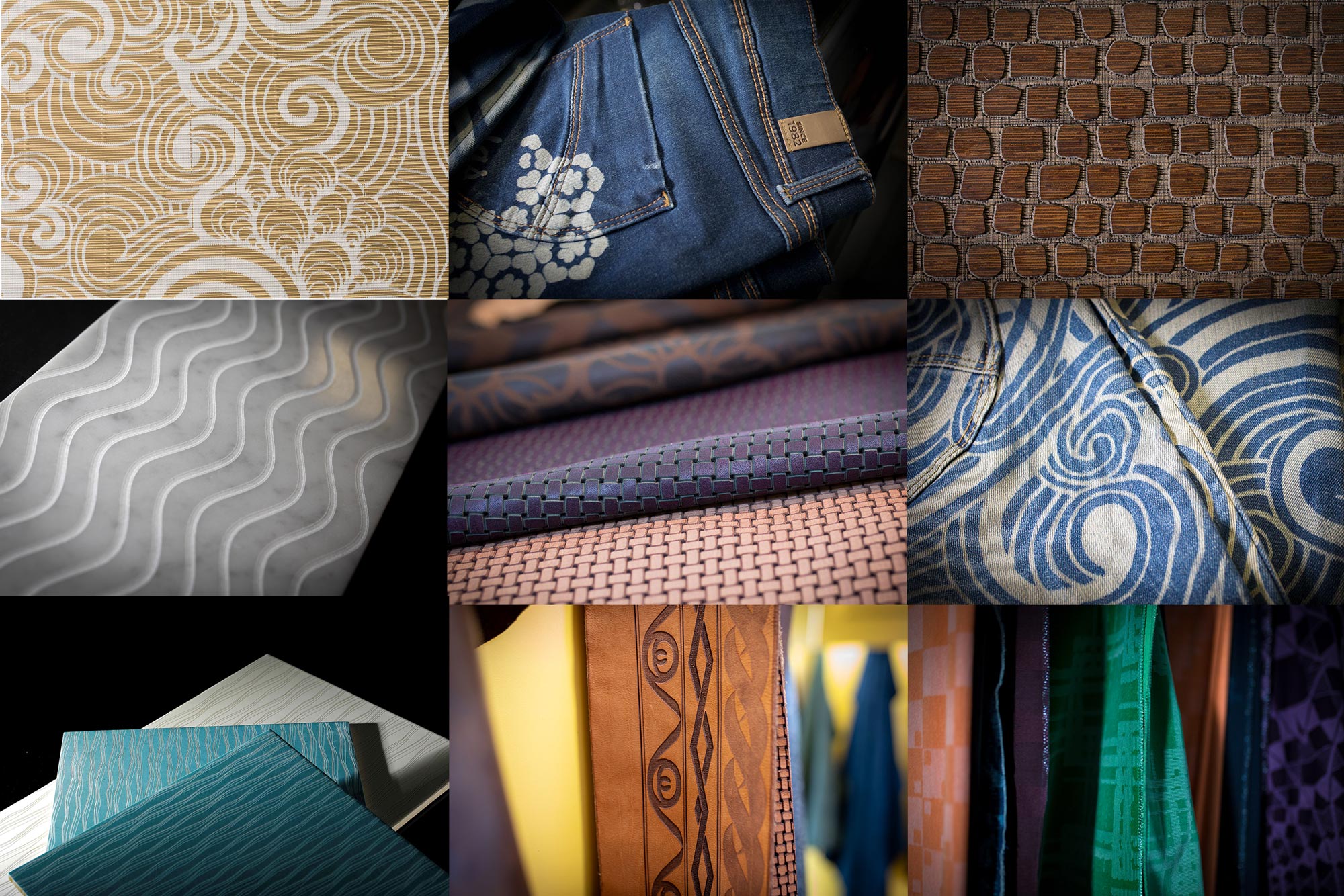

Machines for laser engraving are suitable to work a wide range of materials, minimizing the waste thanks to their extreme precision. A CO2 laser machine can process organic materials, such as leather, marble, wood, paper and food, as well as inorganic materials such as plastic, synthetic fabrics, films and thermoformed. One of the advantages of laser is its low risk of damaging the material compared to mechanic processing, since it is a thermal processing without any contact with the tool. Before buying the laser machine for the company, it is essential to check whether the material to be engraved complies with laser processing.

Speed and Power of the laser machine

The laser system performances are another crucial parameter for choosing the correct machine. If the engraving quality is very important, power and speed are also to be taken into account, based on the material to be worked and the type of production. In particular, a high-power laser machine allows best working of even the hardest materials, with optimum finishing. Moreover, the machine speed has an impact on the entire production cycle, such as the quality of result. Saving money during the purchase because attracted by a lower price and getting a low-quality laser machine would be a very serious error of assessment.

Laser machine size

The laser engraving and marking systems have a considerable size. Some production companies, such as Ot-las, also manufacture compact laser machines or tailor-made systems based on the customer’s needs. In any case, it is good practice to carefully measure the area where the laser machine is going to be installed, to make sure that it can be best placed in the manufacturing department.

Size of the parts to be engraved

The working area available on the machine, in relation to the resolution, is also crucial in the choice of the ideal laser system. Not all laser systems are suitable for processing on big-size parts, with high precision and resolution, therefore it is essential to check this possibility. Once again, the advantage of obtaining customized configurations makes the difference to have the certainty to get a precious and really efficient instrument for the internal production. Furthermore, the material thickness guides the choice towards the most suitable laser type.

Graphic design software

The processing information sent to the machine depends on the graphic design software. Not all laser machines are equipped with an advanced software built into the system, which would require an additional expense. In this case, it will also be necessary to purchase a type of software that is compliant with the laser machine chosen, which can support the type of processing requested. All Ot-las laser machines are equipped with a proprietary software designed to guarantee high-profile processing also with complex graphics.

For very specific applications, it should be considered that tailor-made software and hardware are essential to obtain the required result with the performances desired, as it happens with the excavation of insoles, for example.

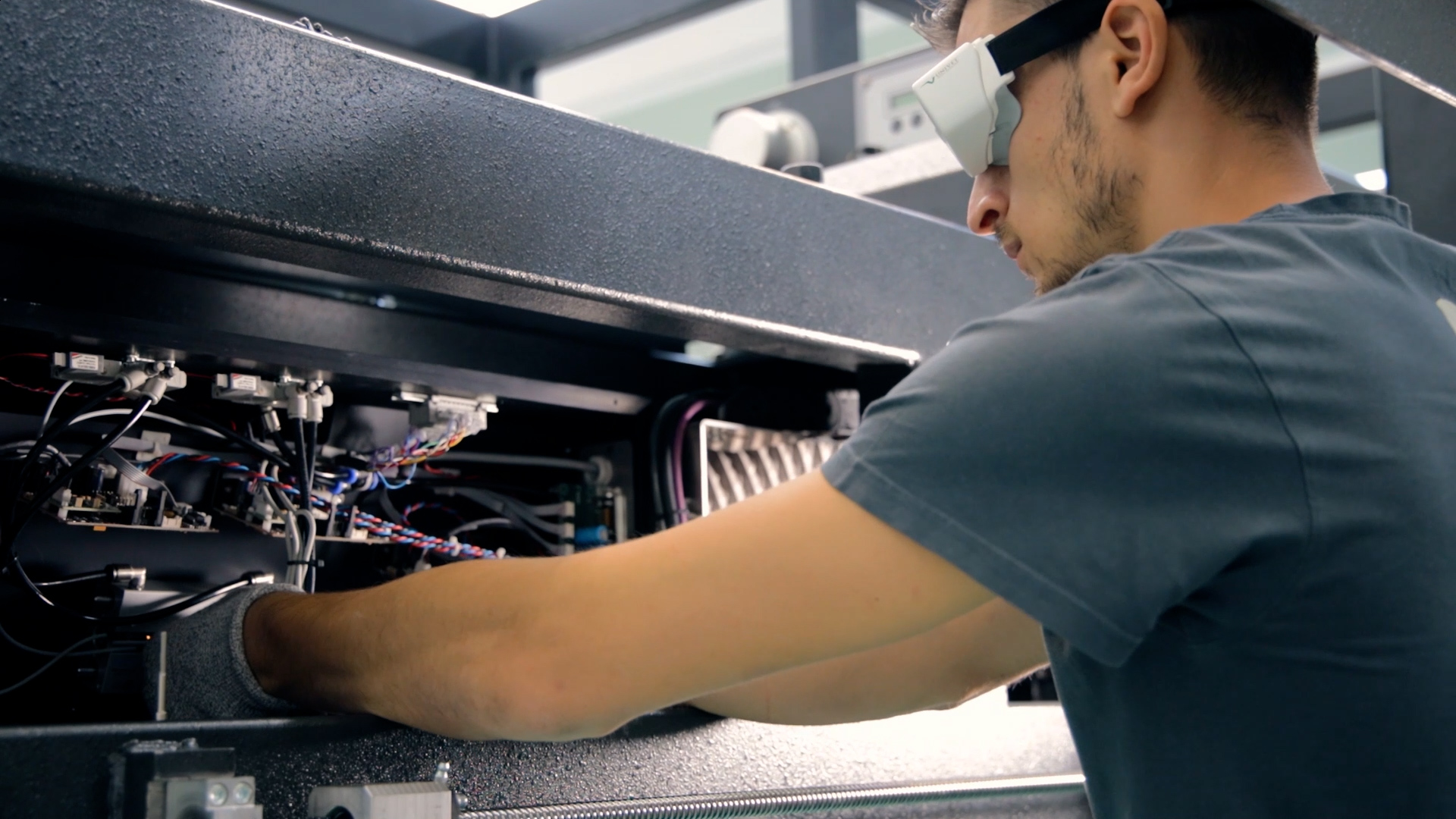

Maintenance and safety of the laser machine

Each laser machine needs maintenance, though to a lesser extent than the mechanical processing systems, since the laser machine is not subject to wear and tear. Before buying a machine, you’d better check the maintenance details and costs to be included in the investment. Knowing the level of assistance supplied to the customers and the capability to implement customized or upgraded solutions by the manufacturing company is also fundamental. The marketing of low-cost laser machines often hides the lack of effective support to the customers for routine and extraordinary maintenance.

A separate question is the safety of the machine chosen, which should be equipped with all necessary characteristics to avoid overheating and risks during processing.

The advantages of choosing Ot-Las laser machines

The Ot-las CO2 laser machines are entirely Made in Italy; they are in-house designed and manufactured so as to offer the best performances in terms of quality, speed and power. The proprietary technology and excellence of processing allows Ot-las systems to achieve any type of graphics and engraving on a wide range of materials. Furthermore, Ot-las engineers and designers are always available to meet the companies’ needs with tailor-made laser machines that can also process large formats. Choosing Ot-las means getting:

- Very high processing accuracy

- Flexibility and possibility of association with other technologies

- Software and proprietary technology

- Direct support for any repairing

- Reliability and safety

- Customized configurations

Find out more about our laser machines or contact us for any further information.