Within our current industrial scenario, increasingly focused on automation and customization, the laser processing systems allow increasing productivity in a sensible and sustainable way.

Due to power and speed performance, first-rate processing can be realized in a very short time. The manufacturing advantages also meet a new focus on the environmental impact that is extremely reduced due to no production scrap and polluting substances while processing. Here is a detailed description of how to boost the company’s productivity by integrating laser technology into operating processes.

Efficiency and speed to increase the product quality

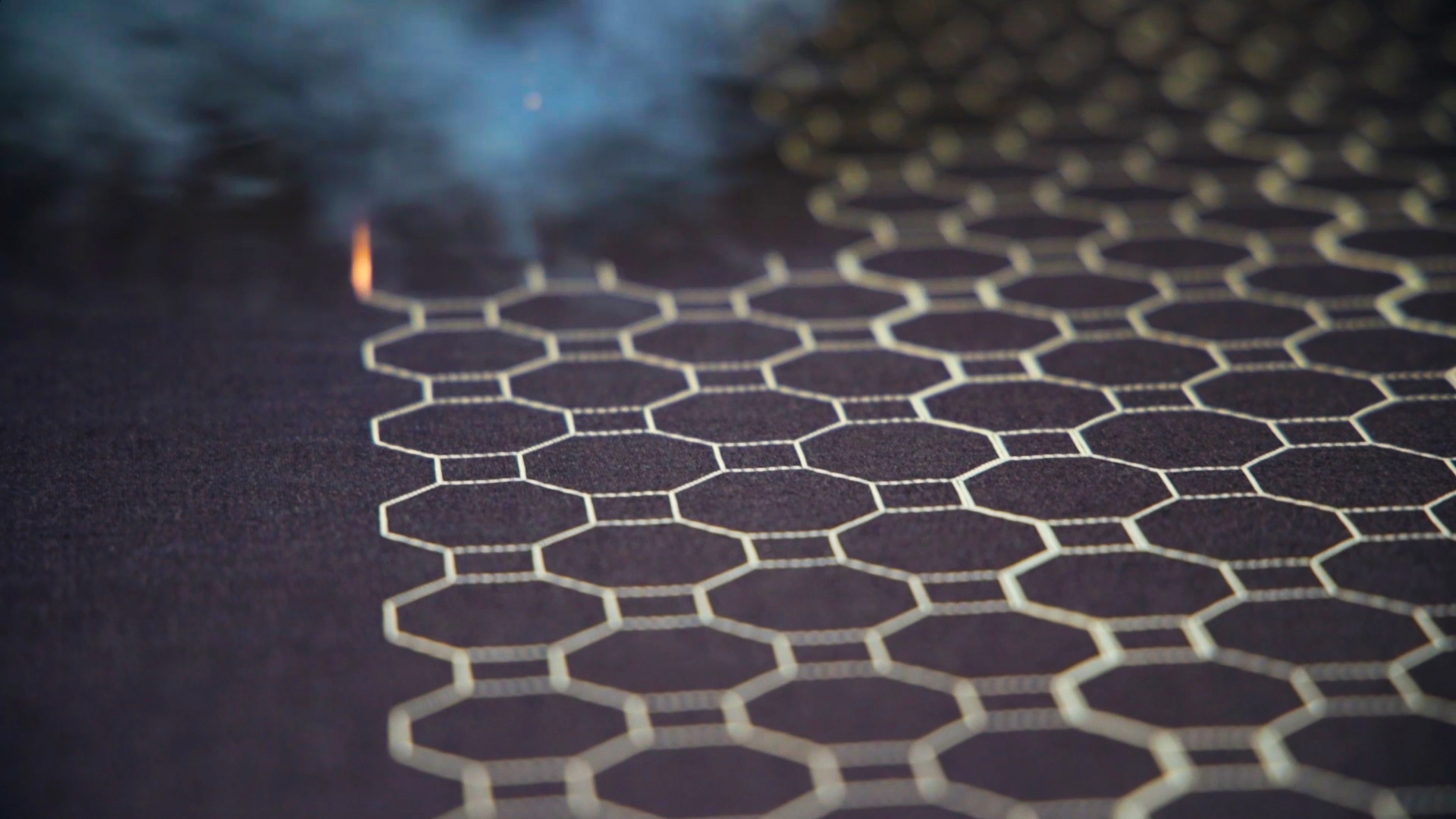

Since the very beginning of industrialization, the need to combine huge demand and short time has ever had to meet quality standards. High quality and manufacturing speed have long been inversely proportional parameters. The laser processing systems have really represented a revolution based on the utmost performance efficiency along with flawless quality. Complex engraving, cutting and marking processing that was unworkable by traditional systems if not with definitely long times, has now become possible. In a few minutes, a quality laser system can carry out sophisticated shapes and patterns with unique accuracy. An essential advantage for companies that are constantly required to manufacture custom-made products for an increasingly more competitive market.

Versatility and integration of laser systems into the company’s manufacturing

Key to the success of the laser processing systems in industry also is flexibility in technology, that can be integrated into the manufacturing cycle. Due to compact and custom-made laser machines, transforming the company’s manufacturing by streamlining performances is now possible just by complying with and speeding up the operating processes. At the same time, the laser technology allows versatility that is totally new to traditional manufacturing techniques. That results in a wide range of endless unique effects along with the possibility of a number of treatments with no tools’ change or downtime.

Productivity growth: the laser in the footwear sector

The footwear sector is the perfect example of how the laser can optimize productivity as well as the organization efficiency. Thanks to laser technology, the various parts of a shoe can now be mounted without necessarily using expert and highly qualified staff. Once the parts have been mass-manufactured, the laser allows easily assembling a shoe without any adjustment by the operator. This way, less scrap is generated from non-complying pieces, thus considerably reducing production waste.

The laser processing systems economy: lower costs and less maintenance

What are the laser machines’ prices? It depends on the kind of system we chose and its performance. The market now offers a number of different laser systems for cutting, engraving and marking. The Ot-Las laser machines are totally designed and manufactured in Italy and guarantee extraordinary performance in terms of efficiency and quality for top-notch processing. The expense for the machine is easily paid back due to production and maintenance cost saving, compared with traditional machines. The laser does not entail the tool’s wear and tear and requires fewer power resources. Furthermore, Ot-Las offers solutions to customize the laser systems configuration, so as to streamline efficiency according to special requirements.

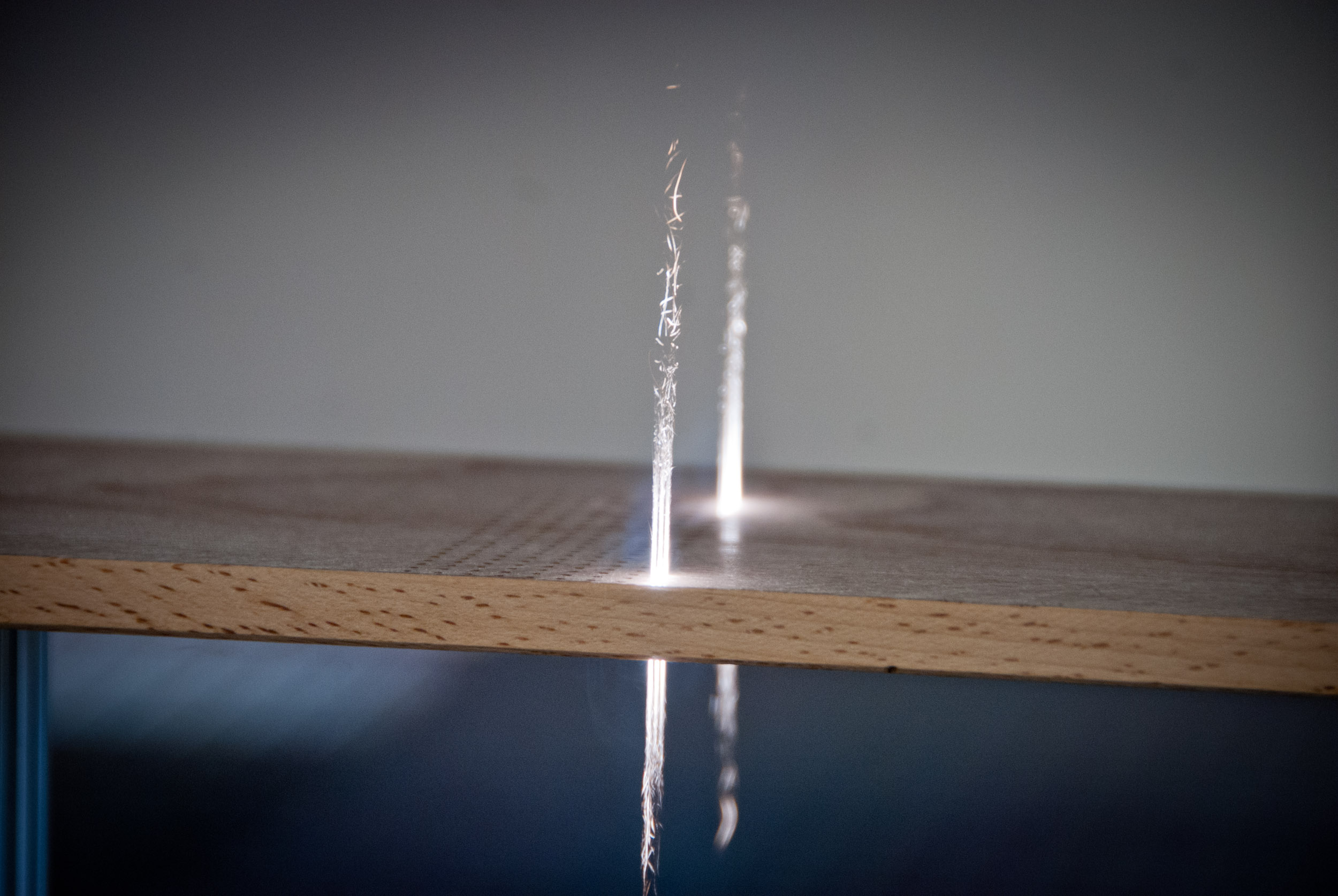

Manufacturing with no waste and chemical substances for environmental-friendly processing

Do you really think any rise in manufacturing necessarily means damage to the environment? The laser processing systems allow increasing efficiency as well as manufacturing volumes in environmental-friendly and sustainable ways. In addition to lower resource consumption, laser processing does not involve pollutants, typically used in many traditional treatments, such as in the textile sector. The only residue from the CO2 laser is the resulting fume that is filtered and harmless before dissolving in the air. Moreover, accuracy in treatments allows considerably reducing scrap, thus preventing any material waste while limiting waste production. That is really environmental-friendly technology for future industry.

Find out more info about Ot-las laser processing systems, specifically designed to increase your company’s productivity.