The new partnership between OT-LAS and FIDIA laser is born, a reference point for architects and interior designers looking for high-profile laser processing on all types of support. To better present the collaboration and its current and future innovation goals, we interviewed Giacomo Perla, laser fashion designer, co-founder of FIDIA and Head of Research and Development for Ideal Blue Spa.

Hello Giacomo, how did the idea of a collaboration with OT-LAS come out?

I got to know OT-LAS even before the birth of FIDIA, working with Ideal Blue in the fashion industry. We were looking for an ideal technology for fabric processing, there were also other companies specialized in denim, but OT-LAS was the only one able to build laser systems tailored to the actual needs of the industrial process.

Two years ago, we founded FIDIA, from the idea of bringing the laser technology also in interior design, where it is not yet well known or applied in an innovative way. OT-LAS has joined the project with two different laser systems, which offer us extensive research and development possibilities.

What applications does the laser find in the work of FIDIA?

FIDIA uses the laser for innovative processing, not only on fabric but also on other materials that have obtained excellent results in B2B. For example, marble, wood and now also glass, customized with laser, are very interesting in the production of bathrooms, doors, kitchens, boiserie and other elements for interior design and architecture. Our research is based on the development of new solutions that meet the needs of this sector both aesthetically and productively.

How do OT-LAS and FIDIA collaborate for innovation?

For interior design there is a need for larger and more particular laser machines, with working areas up to 1.6 m x 3 m. OT-LAS is the only company that makes laser systems for every size. Thus OT-LAS supports FIDIA in its growth thanks to laser systems tailored to the machining needs. On the other hand, FIDIA deals with R&D with different materials, acting as a tester for actual applications and experimentation in interior design.

If the customer of FIDIA is satisfied about obtained work, he could also be interested in buying the laser machine and this is a good opportunity for OT-LAS, while FIDIA has the possibility to acquire new customers thanks to the particular processes it experiments through the OT-LAS systems.

For us it is important to innovate and find out new applications appreciated in the industry and, having a deep experience in laser processing, we are the first to develop certain solutions. So even customers who buy a laser machine consider us a benchmark and can always to us even when they are in surplus production.

How do you find yourself with OT-LAS technology?

With OT-LAS there is a nice ratio because the laser is a beautiful technology that gives few problems, it is really very reliable and does not need much maintenance. In addition, OT-LAS is always available to listen carefully our needs in order to develop new solutions or provide assistance.

As FIDIA, we test new processes, sharing direct feedback to OT-LAS to evaluate together the achievements. In this way also OT-LAS can present to customers finished samples obtained with their systems.

Why is it important for customers to see the final result?

Because finished samples allow you to immediately see what the laser can do, by combining it with other machining processes, such as painting, enamelling etc. This is essential because often the customer does not imagine the real potential of the laser technology integrated in the production cycle and the concrete results that can be achieved. At the same time, by showing the work of FIDIA, OT-LAS promotes its experience and know-how in manufacturing.

What perception do customers have of the potential of laser in interior design?

Our customers are mostly aware of the potential of a cutting laser machine but have a limited perception of the possibilities that the galvanometric laser system allows in terms of decorations in interior design. This is also due to the unexciting experience they have had with samples that have been roughly processed, or with too long time as obtained with unsuitable laser machines. On the contrary, OT-LAS laser machines combine efficiency, versatility and productivity.

Processing carried out with unsuitable laser machines can increase costs and production times, as would be the case, for example, with flat cutting machines, which have excellent finishing quality but processing times not available for many markets. With the right machines and the know-how that we have developed in FIDIA, we obtain beautiful processes, in compliance with a cost and timing range that is advantageous. It is important to offer the right combination of aesthetic refinement and production convenience so that these can be transformed into industrial concreteness.

So the galvanometric laser system meets the needs of interior design?

The beauty of laser is that it allows you to create both large series and contract solutions. It could happen to perform machining on surfaces of 1600/2000 mm or to make realizations on 10 or 20 pieces at most. This extreme flexibility allows us to satisfy the needs of interior designers and architects who are looking for unique and highly customized solutions.

It must be said that sometimes, even in high-end interior design, it happens to see a certain standardization so there is a lot of room for innovation, even starting from an established trend. The trends in interior design are not as ephemeral as in fashion, they last a few years, and in those years it is possible to refine them with new solutions. An example is the 3D material effect that has been in use for a long time in interior design surfaces and that can be easily achieved with the laser.

What are the next goals in the collaboration with OT-LAS?

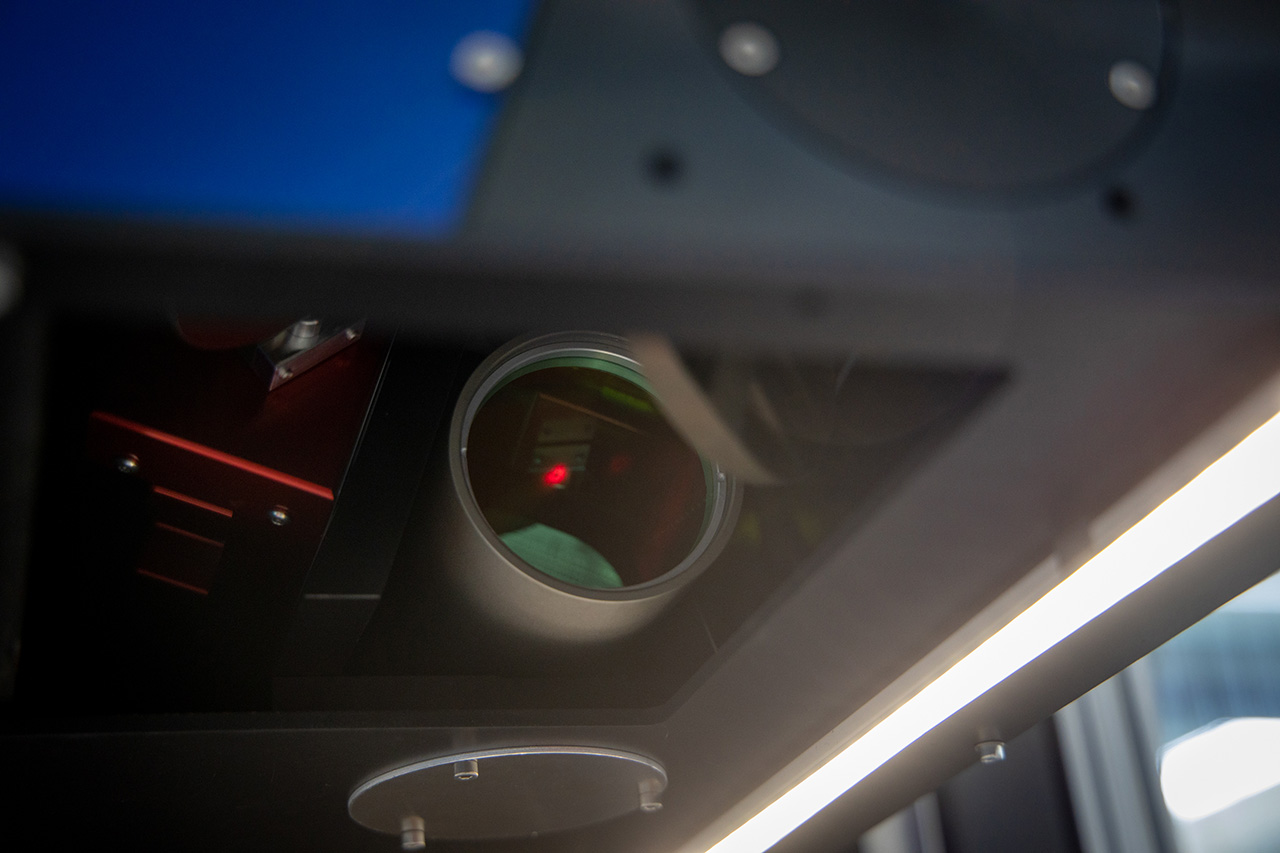

Our common goal is to obtain more and more power onboard of the machine even if with the current technology we can achieve very special machining in a short time. With even more power, we can experiment more with more engraving depth while maintaining the same processing time. At the moment we are very happy with the laser system with 850 W power, which is the perfect combo of speed, definition and modulation. OT-LAS also produces systems with greater power but for the moment this is ideal for us for delicate machining.

As for the materials lately we have experimented a lot with the workings on wood obtaining excellent results. Now we want to focus on laser processing on glass, which is a very difficult material to work with because it is very delicate. The work is coming out well and we want to move on with the R&D in this direction. Laser procesing wood and marble are already used in interior design, while glass is still a novelty because at the moment the only decorations on glass are adhesive or screen printing. The laser instead offers much more interesting potential processing.