The paper industry is now opening up to new horizons of growth: the laser for paper processing is more than a reality.

Companies manufacturing paper and cardboard products, or the printing presses that daily print, cut and engrave paper can now rapidly process it, without bringing about loads of powder and scraps and nevertheless with unparalleled flexibility and creativity.

Some years ago, someone called it the revolution of the laser for paper.

Out of heaps and piles of paper, cardboard sheets, packets and boxes, a new technology has emerged to cut and engrave paper.

The laser for the paper industry is nowadays a fact.

The laser to engrave and cut paper: what are the beliefs entrenched in this sector.

Up to some years ago, laser technology applied to the industry paper was almost unknown.

As a matter of fact, differences are significant and what is inexplicable is why few companies opted for the laser as a technology suitable for cutting paper, cardboard, stickers, labels, in consideration of the advantages resulting from the use of laser systems for paper.

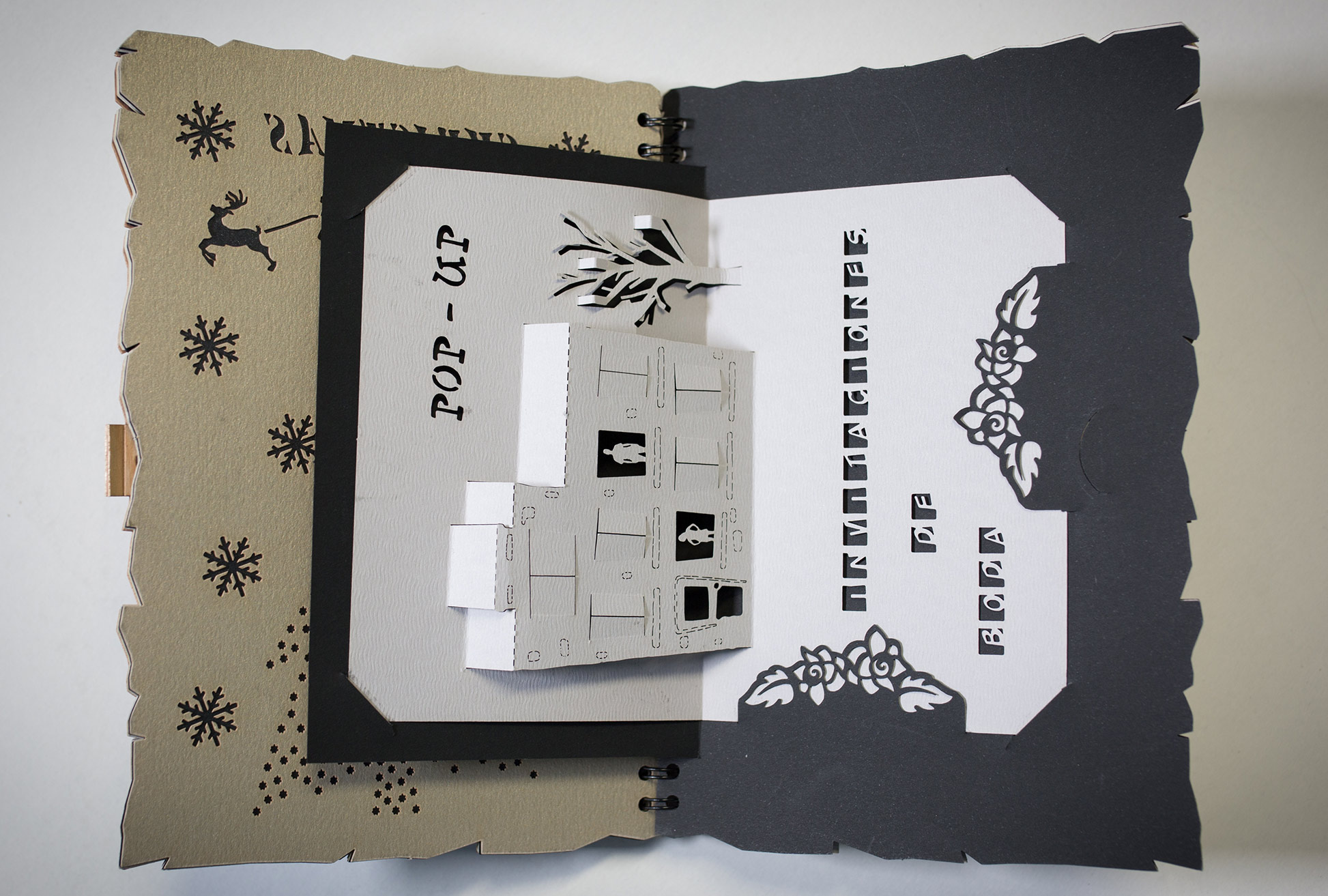

The main advantage is the possible expansion of creativity in the realization of new products. A traditional dieboard will never allow manufacturing objects, materials or carry out paper or cardboard articles, of different types and shapes as is the case with a laser machine.

In this particular situation (as we will explain later) lies the ideal condition for a competitive advantage to be unequalled in the industry paper.

The operators really know the high performance of the laser for paper and cardboard

In the paper industry there is increasingly more interest in the various applications of the laser systems. The operators, by simply looking at the result on a laser-processed paper sheet, still remain astonished by the final outcomes.

It is not just a question of accuracy in cutting though it is definitely true that the laser can engrave and cut with an increasingly sharper “profile” that is slighter and flawless. Nevertheless, it can offer something all traditional techniques cannot: creativity, flexibility, manufacturing responsiveness, even on a mass basis.

You may believe ‘printmakers’ prefer using mechanical dieboards as well as the well-known flat-bed and cylindrical, as they have already been “depreciated” in years of laboratory, workshop or in-house use.

Anyway, what happens when the demand for a certain supply suddenly changes in sizes, shapes, details of execution? How long would it take a printmaker to go back to manufacturing with the right dieboard?

This aspect is even more significant when the demand for certain supplies, for instance special packaging, limited edition objects, gifts or limited-run books necessarily requires small quantities. In such cases, confirming the order is not possible if your firm is equipped with traditional dieboards only: costs exceed proceeds.

We perfectly know, as Otlas manufactures machines that meet the paper industry’s needs, that the competitive advantages (that involve turnover and manufacturing costs reduction) are far more worthwhile and higher.

Who has really found out the benefits of the laser for the paper industry?

The ultimate interest in the laser technologies applied to paper and cardboard is right from graphic, creative artists and designers.

Such professionals, that are regular clients of printing presses for the creation of innovative packaging and packing materials – after seeing the amazing results achieved through laser processing – started asking manufacturing companies for the names of firms able to realize mass paper and cardboard prototypes and processed products.

That was because their regular suppliers still are not in a condition to provide rapid customized processing (both mass or one-shot), that can be got through a laser cutting and engraving system for paper. It may seem a paradox but this is what it is.

Designers, graphic and creative artists cannot find suppliers able to offer a prompt reply to their needs of increasingly higher creativity and these do not arise out of ‘a tantrum’ typical of creative wit but of the market requirements necessary to face the brand placement needs along with the customer retention strategies.

Year after year, the laser systems for paper engraving and cutting will be increasingly more popular, also fostered by a desire we all have that is having a really bespoke product. What if I could count on a laser machine to produce pop-up books or interactive books for children! That would certainly be an advantage for companies dealing with paper.

Being able to offer a service for unique object manufacturing, and produce even low quantities of them by a very rapid cutting and engraving laser system, undoubtedly allows making your way and being ‘a cut’ above the rest in the paper industry sector.

What companies really expect of laser systems for paper and cardboard engraving

Not only is laser use increasingly required in a number of different fields every year, the manufacturers as well as the laser technology assemblers (and there is a considerable difference between them) increase too.

This is another advantage a paper industry company can benefit from in order to reduce manufacturing costs. A manufacturing company, especially if Made-in-Italy certified, does not simply offer a laser machine for paper and cardboard cutting. A company such as Ot-Las is able to design and build the customer’s bespoke machine.

Some years ago, the sector’s trade fairs and events started including foreign manufacturing companies that were European, American, Chinese, whether directly or indirectly represented.

Though variety and diversification of the laser machines’ formats really were considerable, something still was to be found out so as to completely meet the needs of printing presses, laboratories and all of the creative workshops dealing with paper.

Something that made any investment in technological breakthrough really worthwhile, that is support, service and ongoing presence that a foreign company certainly cannot guarantee though operating in the Italian territory.

Something that Ot-Las can instead guarantee every day: laser machines are designed together with the customers, paying attention to their special needs only with a view to improving manufacturing in terms of time and creative opportunities.

Main advantages of the laser for the paper industry:

- High precision to cut or mark complex shapes or patterns

- Excellent cutting quality

- High processing speed

- No thermal deformation

- Variety of processing types (cutting, ablation, engraving)

- Endless duration of the main cutting and marking tools

- No contact between the laser head and the paper surface

- Absolute control and real-time change of the laser power

- Green processing: reduced environment impact without using polluting inks or chemicals

The laser systems – especially those addressed to the paper industry – are perfectly suited to offer high-flexible processing, that is good for both small or large-sized sheets and printed paper to be precisely engraved or cut, even in case of post-manufacturing printing.

No dieboard or cutting plotter can reach the laser performance in the realization of graphic objects with similar precision. Even more, if very complex and detailed elements to be cut are involved.

A graphics-based company, or one operating in the paper sector, in addition to the usual dieboard processing services can now expand its use fields due to the Ot-Las laser systems. Adding more services, with a view to entering new markets and involving new customers, simply contributes to higher markups.

Find out all those features and potential that the laser cutting and engraving systems can involve in your company’s growth.