Are you looking for a laser marking machine tailored to your needs? CO2 laser marking is an advanced and versatile solution for many industrial applications. Thanks to the precision and efficiency of laser machines, you can count on a level of customization and productivity that was previously unattainable. Furthermore, the laser is a green technology with low energy consumption compared to traditional methods, with benefits also from an economic and environmental point of view.

Not all laser machines allow you to process even large dimensions or with customized configurations. Let’s see what the advantages of tailor-made laser marking machines are suitable for customersd and how to choose the most suitable machine.

The importance of customization in CO2 laser machines

CO2 laser marking is a process technique that is increasingly requested in many sectors, from automotive to fashion, from packaging to footwear up to accessories and interior design. In each of these markets, customization is an essential factor, as it is requested the possibility of adapting your laser machine to specific needs. The advantages of a custom-made laser machine include, for example:

Operational flexibility of processes and materials

Customized laser machines are designed and developed to process a wide range of materials, such as plastics, natural and synthetic fabrics, stone, glass, ceramic, paper, leather, all of them based on very specific needs. For this reason the configuration of such machines completely satisfies the strict request of the market in which they operate, assuring operational flexibility at the same time.

Optimisation of production processes

The customization of a laser machine allows you to get specialized results and to optimize the marking process, reducing processing times and improving the quality of the final product.

Diversification and market opportunities

The employment of tailor-made laser marking machines allows you to open new markets and to expand your own, with services and products capable of responding to the constantly evolving needs of your customers.

To save operative and engraving costs

A machine configured specifically for your business needs leads to reduced operating and finishing costs, without wasted material or wasted time for adjustments or modifications. But above all it allows you to make the finished product unique and inimitable.

Customized laser machines: the criteria to be evaluated

The choice of the laser marking machine is fundamental to be sure it is suitable for your production needs. For example, the dimensions of CO2 laser machines can vary significantly, and the evaluation of the right size depends on several key factors:

- Size of the material to be engraved: the machine useful area must be large enough to position the material on the working area, but not too large to preserve resolution and efficiency

- Production volume: for high volume productions, a machine equipped with high laser power, or suitable working area or specific automation of the pieces may be required.

- Available space: the size of the machines are often chosen depending on the place available in the company, integrating into the production cycle, preserving efficiency and safety of the personnel involved.

Before to invest in a custom laser system it is best to consider these aspects to ensure you get the ideal marking machine for your company.

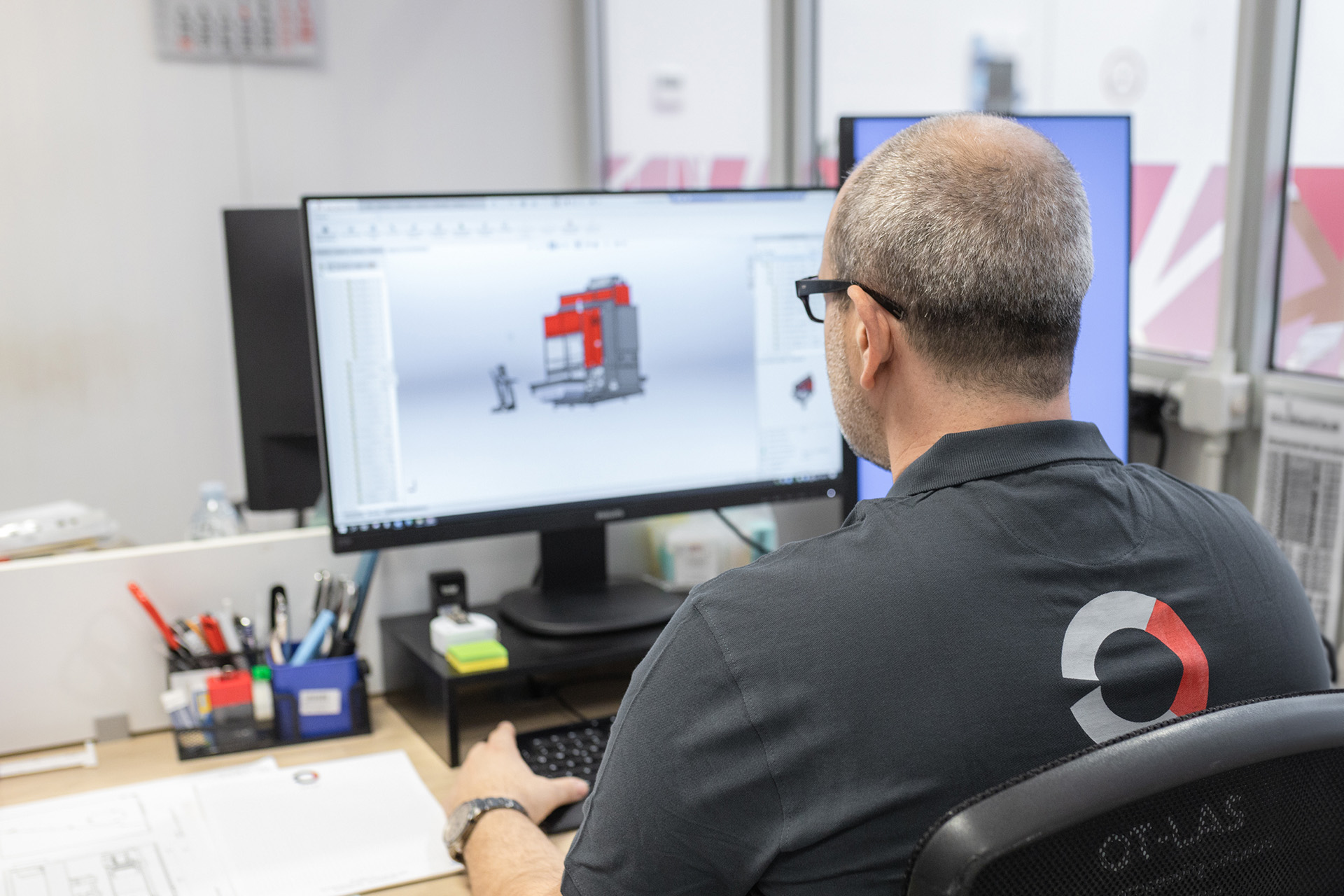

OT-LAS laser marking machines tailored for each application

OT-LAS designs and develops customized laser systems for your production needs. The internal and Made in Italy supply chain, combined with specialized technical support, allow you to have a laser machine that meets your needs. Many customers have already chosen this opportunity to access all the advantages of the laser and expand their market. Thanks to the creation of customized laser marking machines by OT-LAS you can:

- To receive expert advice on the best options to achieve your machining goals

- To Request a customized project based on your needs

- To Present your project to us and to proceed with tailor-made production

- To update laser machines with the latest technologies and features available, maintaining the company’s competitiveness

- To Configure an OT-LAS laser system with working beds, laser powers, automations or customized software solutions for your company

- To receive dedicated technical support and assistance to quickly resolve any technical problems or operational questions

Contact us to request a laser engraving machine customized for your company