Laser marking and digital printing technologies are among the most used for the personalization and identification of packaging, products and accessories. The laser in particular offers unique advantages in terms of quality, sustainability and efficiency. Compared to other printing techniques, such as pad printing, digital transfer or doming, CO2 laser marking and digital printing increase the productivity and accuracy of print results. But what are the main differences between the two solutions and which one should you choose for your company?

How does laser marking work?

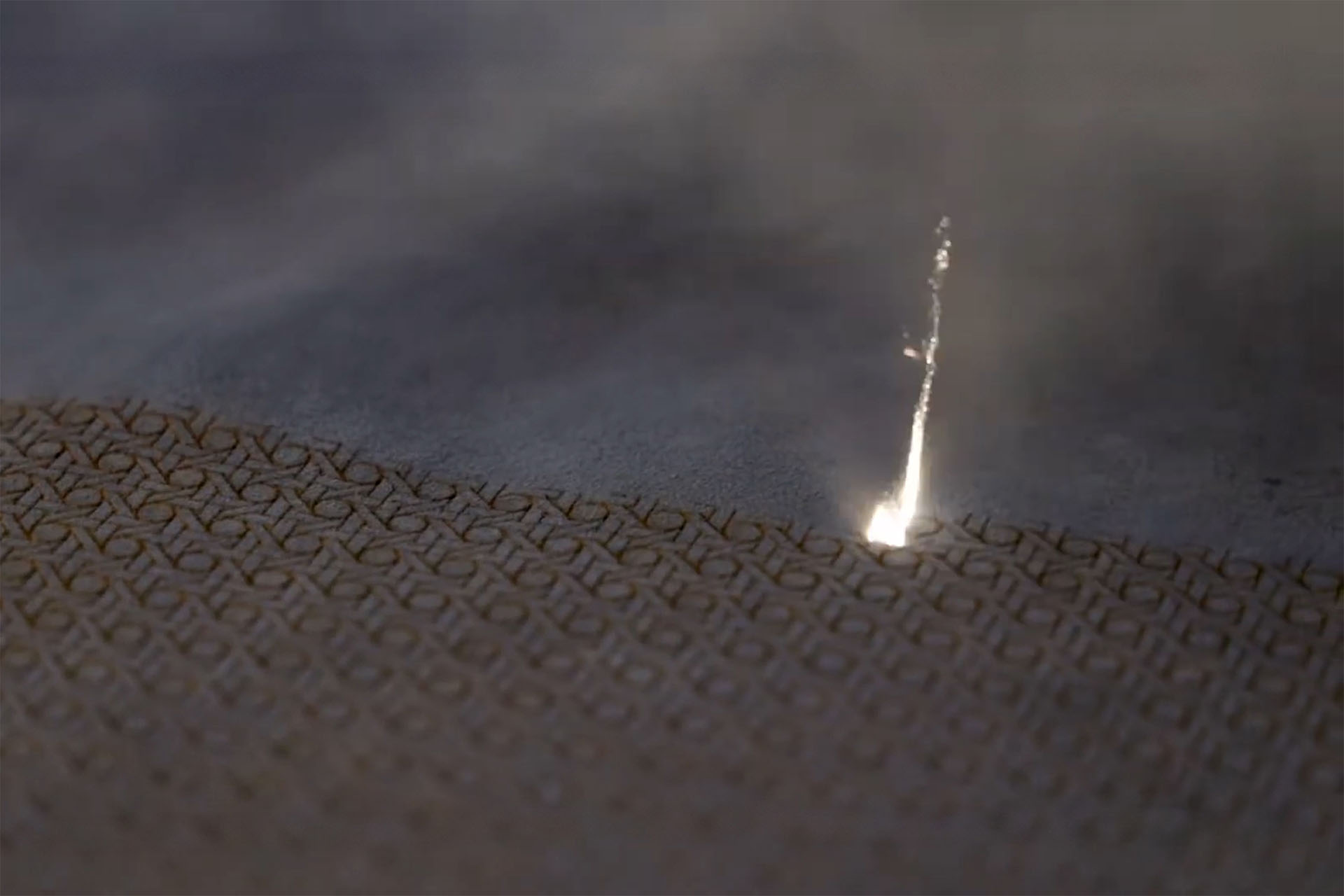

CO2 laser marking is an advanced technology that allows permanent writing, drawing, pattern, logo and numeric alpha codes to be made on a wide range of materials. A highly concentrated infrared beam of light locally heats the surface of the material, generating chemical or physical changes based on exposure time and operator-defined parameters. The final result is a change in colour of the marked surface, with more or less strong contrasts, and a permanent marking with very high precision and customizable depth.

Laser marking types according to applications

Laser material processing machines allow to obtain a range of unique effects of exceptional quality and versatility. Depending on the applications, you can also choose between:

- Surface marking, which changes the color or structure of the material without removing it.

- Laser engraving, which sublimation a part of the material with a depth determined at the time of programming the machine.

This flexibility allows laser marking to meet numerous production requirements and also to work with materials that vary widely in terms of strength and type of surface, including wood, plastic, thermoformed, marble, glass and even textiles.

What is digital printing?

Digital printing is a process that allows a digital image or text to be transferred onto the surface of the chosen material. Digital printers apply ink or toner directly to the material, creating accurate and vivid prints without the need for plates or dies. For this reason they have replaced other printing methods such as tampography or screen printing in many sectors. However, they have some limitations regarding the treatable surfaces and environmental impact due to the use of polluting inks.

What are the characteristics of digital printing

Digital printing is very suitable for small runs and quick customizations, but requires a treated surface that is smooth enough to ensure optimal ink adhesion. The image obtained is more resistant than that produced by techniques such as tampography, ceramic transfer or doming, but less resistant than laser marking, since the application of ink is extremely superficial.

Laser marking and digital printing in comparison

How to find the best way to personalise and track products? Here is a direct comparison, step by step, between CO2 laser marking and digital printing techniques:

1. Durability and resistance to machining

One of the major advantages of laser marking is the guarantee of permanent results and resistant to abrasion, time-lapse and exposure to moisture and atmospheric agents. Digital printing, although durable, can fade over time, especially when exposed to harsh environmental conditions. Furthermore, as it is a surface imprint, the result obtained may be compromised by scratches and abrasions.

2. Quality of the final result

CO2 laser marking is known for the precision more than millimetric guaranteed by the high definition optical system and the reliability of the laser machine offered by some manufacturers, such as OT-LAS. For these reasons, the laser is also ideal for making complex details, QR codes, drawings and logos. It also allows to obtain clear and precise results even on uneven surfaces, increasing the range of treatable surfaces. Digital printing offers excellent visual quality guaranteed by the digitization of the process and the wide range of inks. However, it may suffer from adhesion problems or loss of sharpness on particular materials, depending on the porosity of the treated surface.

3. Versatility of the materials

CO2 laser machines are designed to mark and engrave a wide range of different materials such as:

- Plastic

- Fabric

- Glass

- Wood

- Skin

- Marble

- Ceramic

- Acrylic

- Films

- Thermoformed

Direct printing is applicable to materials that have been properly treated or with surfaces suitable for ink adhesion.

4. Speed and automation

Both laser and digital printing offer decisive advantages in terms of productivity over other printing techniques that require the application of masks or film:

- Laser marking is extremely fast and can be integrated into automated production lines, guaranteeing continuous machining without machine stops for job changes.

- Digital direct printing, while a fast process, does not always respond effectively to large-scale productions, thus demonstrating an advantage related to the size of the project to be addressed.

5. Environmental impact and sustainability

The introduction of laser marking and engraving has also led to an improvement in terms of sustainability in the processing. In fact, no inks or solvents are needed for laser marking. The smoke generated by the process is readily aspirated and the entire process produces less waste than digital printing and screen printing. Ink residues are the great disadvantage of digital printing, producing a greater environmental impact.

Advantages of laser marking compared to screen printing

Another technique commonly used in the printing of images and codes on packaging and products is screen printing, which involves the application of inks through a screen printing network. This technique has been progressively replaced in many areas by more modern techniques, as it has some limitations. Compared to laser marking, screen printing:

- It offers a variety of bright colors, but the duration of the result is much shorter because the prints obtained are more subject to wear and tear from time and weather.

- Requires long and expensive preparation processes, especially for limited runs, compromising production efficiency.

- Like digital printing, screen printing has a greater environmental impact than laser due to the use of inks and solvents.

Competitiveness and efficiency of CO2 laser marking

In comparison with the printing techniques considered, laser marking is therefore the most effective tool for writing, drawing and coding on different materials with an elegant and durable result. Buying a laser machine may require a higher initial investment than direct printing but it is soon rewarded by valuable operational, economic and environmental advantages such as:

1. Cost-effective

Even if the cost of purchase is higher, laser marking reduces long-term operating costs by eliminating the need for consumables such as inks or toner and their disposal.

2. Advanced customization

With the laser it is possible to create unique and customized designs with extreme ease, adapting to the customer’s needs in real time.

3. Environmental sustainability

The reduction of material waste guaranteed by the laser’s very high precision and the absence of chemicals in the processing make the laser a sustainable and environmentally friendly choice.

4. Industrial adaptability

Thanks to the versatility offered by laser marking, this processing technique is used in many industrial sectors. The main ones include for example:

- Packaging (logos, graphics and information texts)

- Food packaging (expiry dates, traceability codes)

- Design (customization of accessories, objects, fabrics)

- Fashion (graphics, drawings, lettering, exclusive effects on fabric and leather)

- Automotive (serial numbers, QR codes, interior design)

- Advertising (personalization of signs, cardboard, flyers and gadgets)

The OT-LAS laser machines for a Made in Italy customisation

The choice between laser marking and direct printing depends on the specific needs of the project, however, the laser is the most advantageous solution in terms of high precision, low operating costs and environmental sustainability. If you want to adopt an advanced, reliable and innovative laser marking technology for the customization of your products, it is essential to focus on high quality laser machines. For over 40 years OT-LAS has been designing and manufacturing laser machines for engraving and marking using the latest technology, which are entirely manufactured in the company. The high standards of Made in Italy guarantee excellent performance in every application with exclusive and defined marking effects. In addition, our technicians are always at your disposal to meet your production needs even for large format operations.

Contact us to find out the laser marking solution tailored to your company.