Leather is a versatile material and widely used in the clothing, furnishing and automotive sectors. Through laser cutting, results are obtained that are valuable, cured and long-lasting. Nonetheless, laser processing of the leather also presents difficulties, which we are able to manage with our instruments.

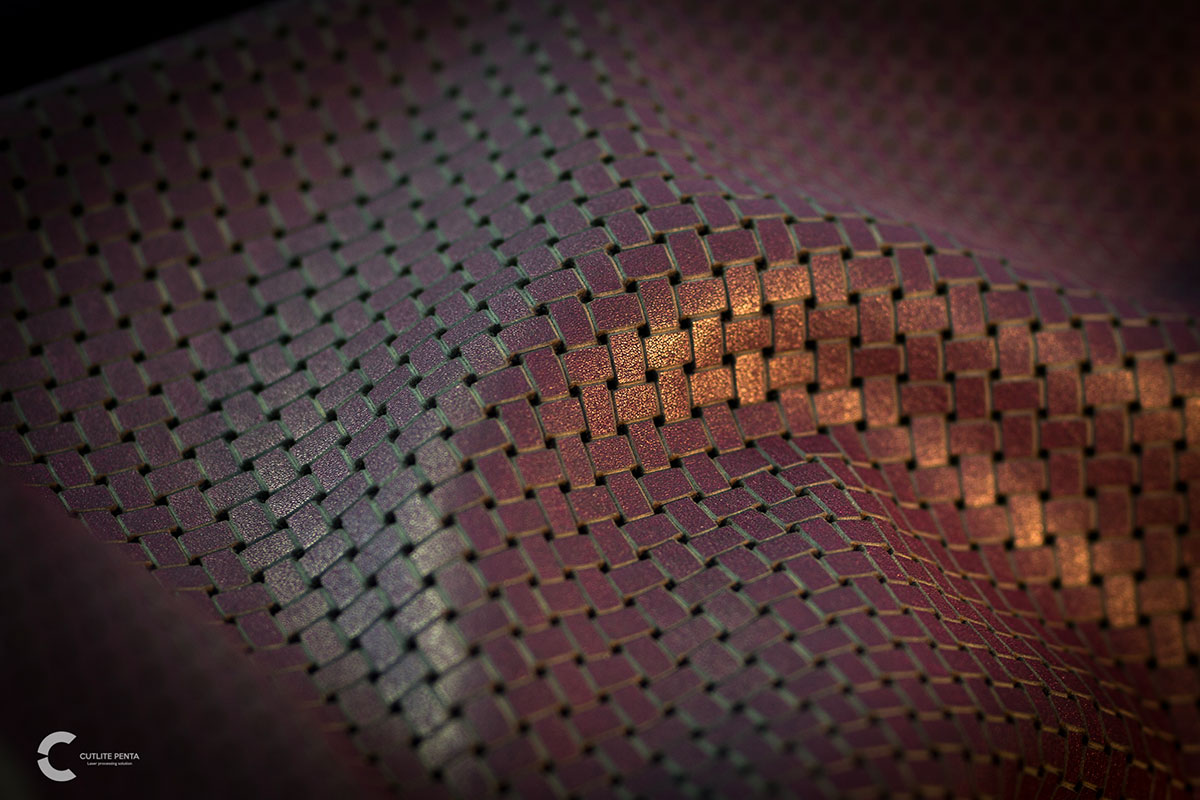

The decoration, marking, cutting and laser cutting of the leather are part of the production cycle defined as finishing, which then gives the final visual and tactile result. This depends on the tanning used, on the leather and also on any finish already present. The laser is in fact the last place among all the finishing operations. Thanks to the collaboration with specialized companies in the sector, some techniques have been developed to give the leather a particular look and feel. Each operation is carried out to enhance the natural appearance of this material and to bring out its softness.

Furthermore, by means of advanced cleaning systems, it is possible to remove dirt and eliminate the odor caused by laser processing.

This procedure is carried out through chemical and mechanical processes:

- whisking to remove dirt particles

- chemicals that neutralize the smell permanently

Leather processing is a very complex and delicate process and this is due to the organic nature of this material, which must therefore be handled and used with care.