From 24 to 27 September 2024, MarmoMac come back to Verona, the most important world fair dedicated to the stone production sector. An unmissable appointment for all companies and professionals working in the sector, from quarry to processed product through machine tools.

OT-LAS will renew its presence to present the evolution of technology for laser engraving marble in interior design. The experience gained in processing and development of cutting-edge laser systems for natural stone processing will be available to all those who want to visit us at the fair in hall 2, stand C3 -D3.

Marble, stone and design: when the laser transforms nature into art

Marble has always been synonymous with elegance, resistance and refinement. It is no coincidence that, since ancient times, its veins and timeless beauty have embellished the most noble environments. Today, laser engraving has revolutionized the world of marble processing, offering new creative and technical opportunities for designers and craftsmen, with striking applications that enchant for precision and versatility. Here are some of the applications that have enriched interior design with new possibilities:

The laser engraving that sculpts environments

Laser engraving applied to marble and other natural stones allows you to personalize the interior and exterior with elegance and precision. Thanks to the ability to manage the heat and intensity of the laser beam, surfaces can be enhanced with refined and continuous details, ensuring repeatability and uniformity even over large surfaces. From columns to frames, from worktops to fireplaces, laser engraving transforms spaces into exclusive environments, with the certainty of obtaining accurate results in every detail.

Decoration without borders with laser marking of marble

Thanks to laser marking, the decorative possibilities are virtually endless. The CO2 laser allows you to engrave logos, lettering, drawings and patterns on any marble surface, maintaining an extraordinary precision even on tiny details. For example, luxury homes and hotels as well as commercial spaces use laser marking to personalise reception areas, floors, walls and decorative elements. Even in the production of plaques or artistic panels, laser marking is an effective and indelible solution that avoids the use of polluting inks and paints.

New textures and material effects in interior design

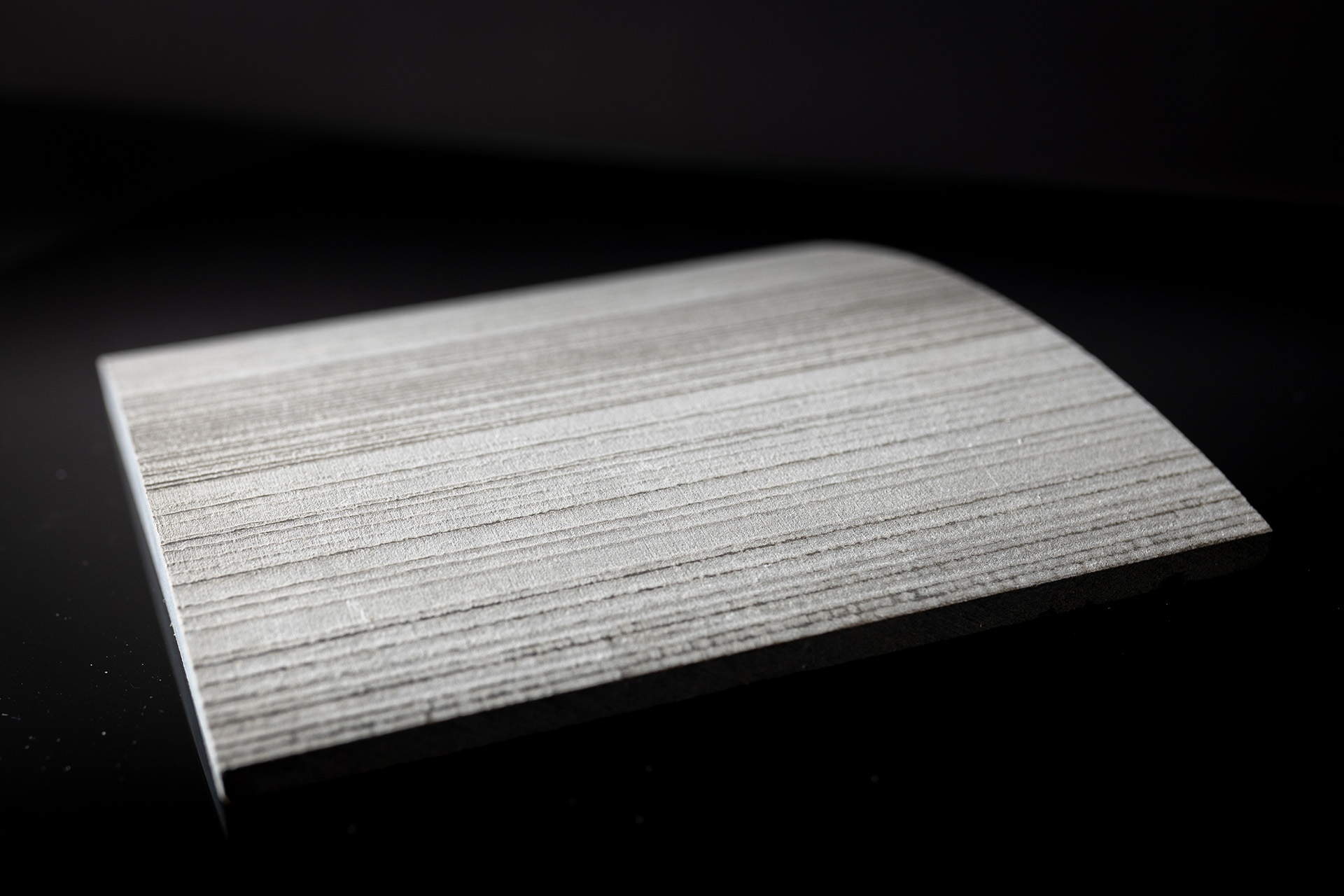

In addition to pure decoration, the laser allows you to create innovative textures that add depth and dynamism to marble surfaces. Laser machines for engraving and marking are not limited to creating graphics and drawings, but can also modify the surface of the material creating material effects that involve touch and sight.

The possibility of obtaining three-dimensional patterns or laser-processed semi-rough surfaces is very popular in interior design to give a contemporary touch to environments. For

example, it is possible to achieve sandblasting effects, controlled scratches and engravings on several levels, with an infinite variety of aesthetic combinations made even more striking if enhanced by lighting. These details amplify the visual and tactile impact of marble surfaces, giving rooms and walls prestige and elegance.

Laser-made valuable elements for furniture

The possibilities offered by laser extend to the creation of custom and high-quality marble furniture. Tables, shelves, lamps and other furnishing accessories can be machined with precision more than millimetric, allowing to transform each piece into a small work of art. Laser engraving allows to create clear and complex lines, ideal for the creation of precious geometric patterns and special engravings on furniture elements, without risk of damage or imperfections.

The advantages of laser technology for natural stone processing

The use of laser for engraving and marking marble is becoming increasingly popular in interior design thanks to its many advantages over traditional methods. First of all, laser technology guarantees unmatched precision and extremely neat and clean work, very relevant aspects for this sector. Laser machines also prevent the wear of mechanical tools and minimize the risk of material damage, an essential advantage when working with valuable materials such as marble.

Another decisive advantage is the considerable reduction in processing times, with a consequent increase in production efficiency. This way, the companies in the supply chain can offer customized and complex jobs in shorter time, becoming more competitive on the market. Finally, the flexibility of the laser allows you to work not only marble but also a wide range of stones such as slate, granite, basalt, sandstone and clay, adapting to the needs of any design project.

Come and visit us at MarmoMac 2024 in Verona to discover the best laser technologies for marble processing or contact us for information.