Is it possible to achieve maximum flexibility of industrial cutting while saving on time, costs and even the footprint for processing? With robotic laser cutting, all these advantages are now a reality. Let’s see how a laser cutting kit for robots increases the precision, versatility and efficiency of your company and what are the main applications in different sectors of industry.

What is a robot laser cutting?

Robotic laser cutting is a technology that combines the precision and versatility of CO2 lasers with the flexibility of industrial robots. Laser robotic systems are in fact suitable for complex machining that require high cutting quality and repeatability. The integration of CO2 laser allows to process a wide range of materials, from plastic materials to composites, up to thermoformed, with impeccable results and without the need for further finishing.

What are the advantages of a laser cutting robot?

Choosing a laser cutting robot system for industrial processing offers several advantages over the use of traditional cutting technologies. These include the following:

- Very high precision of cutting and three-dimensional finishing, without burrs and without traces of carbonization

- Maximum flexibility in the machining given by the robotic arm that allows to execute even the most complex profiles and operate independently of the limits of the work plan

- Automated process efficiency, which reduces processing times, increasing productivity and market competitiveness

- Reduction of overall operating costs, thanks to the efficiency of technology and reduced equipment and maintenance expense

OT-LAS RX: the laser cutting robot with 3D technology

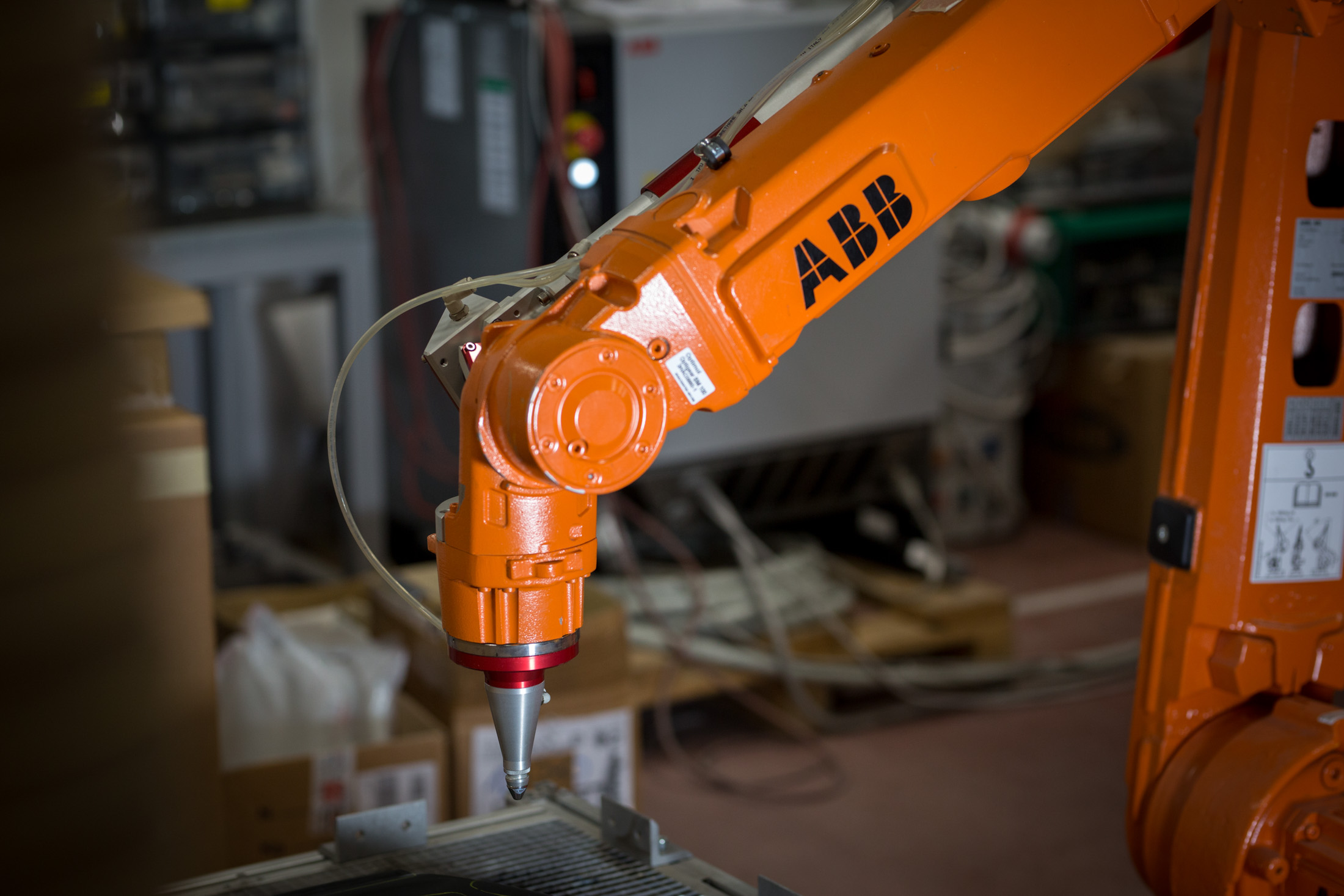

One of the most advanced tools in the field of robotic laser cutting, a system designed to combine a robot with a CO2 laser source through a 7-mirror articulated optical arm. The system allows to make high profile 3D laser cuts with exclusive advantages such as:

- Reduced maintenance (8 hours per year)

- Limited machine stop

- Cabin without soundproofing

- Simplified poses

- No mechanical contact with the tool

- High speed of execution

- Limited operating costs

- Minimum of space

The RX system uses an advanced laser beam guidance system, high-power El.En. laser sources and ABB or FANUC robots. Depending on the configuration, the RX kit can be equipped with:

- Cutting head with lens of 5′ or 7′ for precise and clean processing of thermoformed in ABS, HDPS, carbon fiber, glass fiber, Kevlar, plastics generally, even thick

- Galvanometric scanning head, suitable for thinner thermoforms, less than 3-4 mm, ideal for example for inner liner fridge/freezer.

All applications of 3D robotic laser cutting

The OT-LAS RX robot is distinguished by its ability to perform three dimensional cuts with respect for materials and very high precision. The excellent cutting quality makes it a preferred choice for various industrial applications. In particular:

Automotive

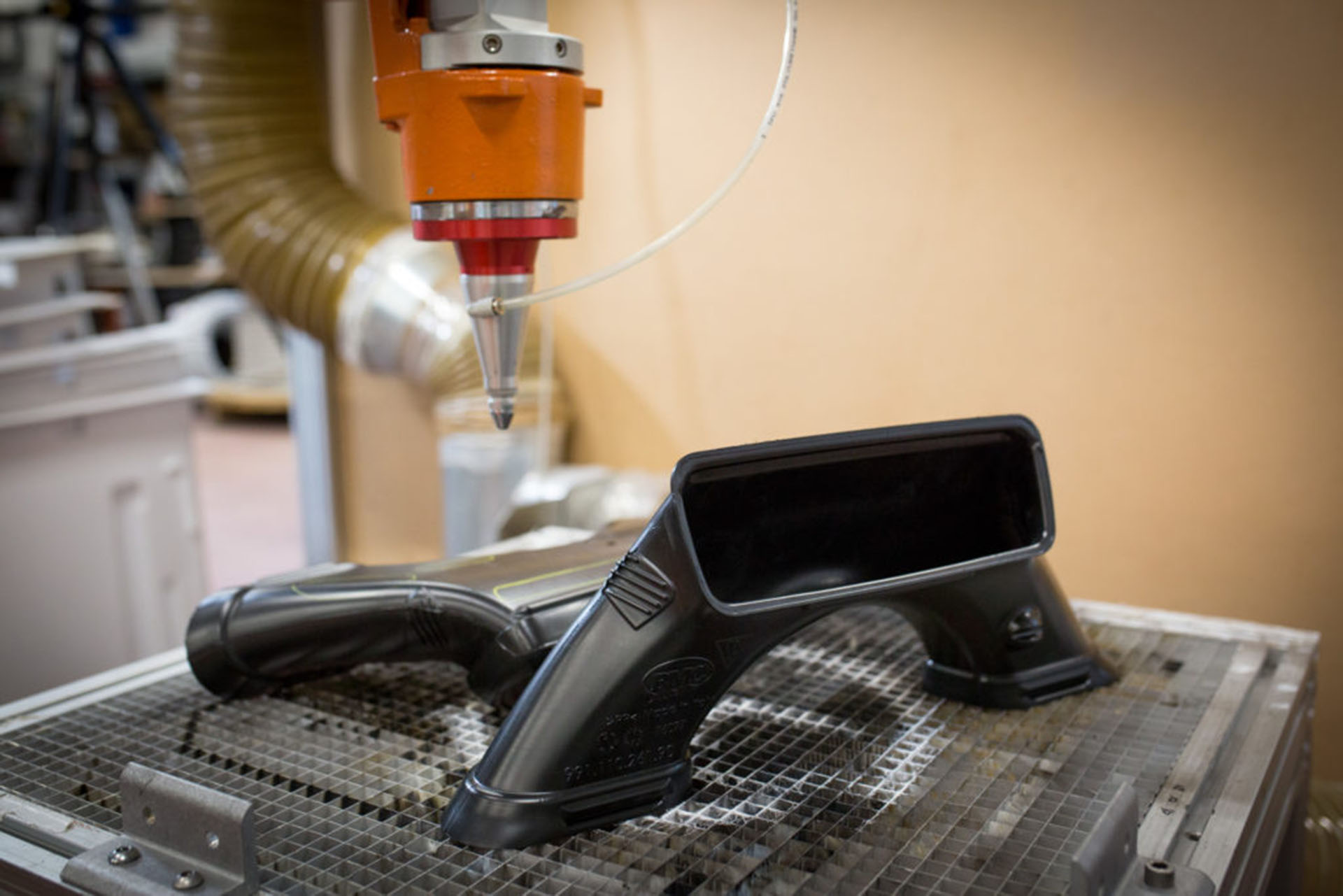

In the automotive industry, laser cutting robot is the best technology for finishing interior components such as boards, bumpers and other blown plastic parts. The precision of the laser ensures that the finished parts are free from burrs and perfectly finished, meeting the demands for high quality and customization.

Home appliance industry

One of the main applications of the RX kit is cutting internal liners for refrigerators and freezers. Thanks to the galvanometric scanning head configuration, it is possible to make fast and precise cuts on thin materials such as ABS and polystyrene, improving production efficiency and reducing machine downtime.

Processing of composite materials

RX is highly effective in processing composite materials such as glass fiber, carbon fiber and Kevlar. These materials, often used in industries such as aeronautics and defence, require extreme precision to ensure that the finished components meet stringent technical specifications and safety of the finished product.

Production of components for helmets

Among the applications where safety is essential, there is also the production of motorcycle helmets. Laser cutting guarantees sharp and precise edges, as well as a wide versatility, allowing the production of different components without the need for further processing.

Discover RX’s robotic laser cutting or contact us to find out if it is ideal for your business.