The galvanometer is an electromechanical transducer that turns electric current into a rotation of its mechanical axis with high accuracy.

Mounting a laser on the galvanometer axis, a laser beam can be deflected on a controlled basis. If the electric control is variable over time, rotation of the galvanometer axis temporarily follows the signal direction. Combining two galvanometers with the axes perpendicular one to the other, the laser beam can draw a trajectory on a plane.

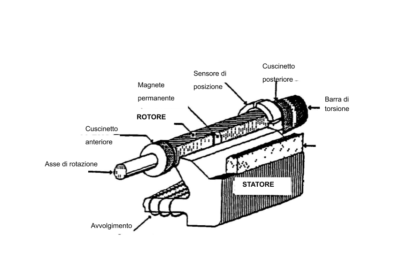

Structure of the galvanometer

The moving magnet galvanometers are those featuring low inertia of the stator and therefore, they are the most suitable for high speed applications.

The galvanometer is made up of two parts:

- the rotor, namely the moving part, is made up of a permanent magnet on which the rotary axis, the return spring and the position sensor are fixed.

- the stator, namely the fixed part on which the automatic electric winding is placed.

A scheme of the galvanometer is represented in Figure 2:

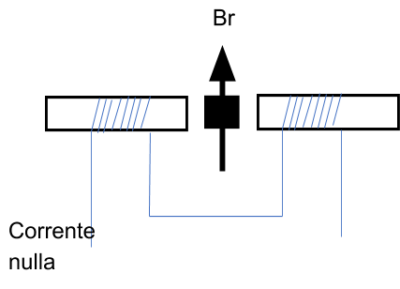

When current does not flow through the stator winding, the rotor magnet is maintained in its zero position by the torsion spring. The magnetic field itself generated by the permanent magnet will take the rest direction.

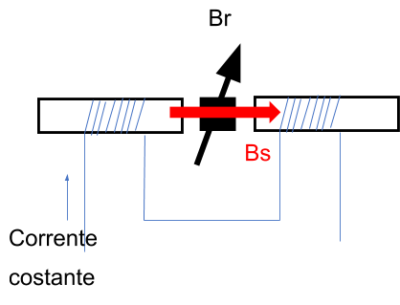

If through the stator winding a constant current flows, this will generate a magnetic field directed along the axis of the two poles that will get the rotor field rotate as long as it balances the force generated by the torsion spring. The rotor’s rotation will in turn rotate the position sensor that will generate a signal proportional to rotation itself. This signal is used as feedback to increase the galvanometer’s accuracy.

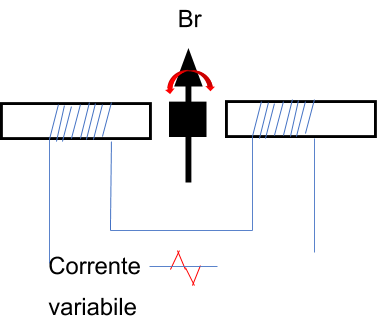

In the stator winding a variable current over time can flow that will generate in turn a corresponding rotation of the galvanometer’s axis. Even the position sensor will generate a corresponding signal.

In order to guarantee rotation around the rotor’s axis, this is equipped with two bearings.

With these moving magnet galvanometers, high performance in terms of both accuracy and rotation speed is reached, making their use essential in the realization of laser scanning.

Galvanometer laser: check and speed for high-profile processing.

How does the galvanometer laser work and what advantages does it offer in processing?

We know exactly how a galvanometer works and so we can better interpret the functioning of a galvo laser. In practice, the mirrors deflecting the laser have been mounted on two galvo motors. This allows reaching extraordinary beam speed as no mechanical parts (accordingly, friction) are involved. Acceleration and the changes of direction are at least 15 times faster than in a ‘mechanical’ motor machine.

Dynamic focusing and remote processing

Another key component is the linear galvanometer on which the focusing lens – said z – is mounted (that is focusing of the distance, the other two mirrors deal with the motion in x and y while the linear galvanometer is for the third axis, that is in fact z) and this lens allows a dynamic focusing. In fact, the galvanometer system head operates at a variable distance from the material.

Changing its position and that of the mirrors’ angles, also the distance changes run by the projected laser beam. Accordingly, the dynamic focusing allows varying the focusing length, so as to guarantee a constant intensity of the laser beam during processing operations.

All advantages of the galvanometer laser:

- Very high acceleration and processing speed

- Reduced processing times

- Little power consumption

- Laser engraving and cutting even of surfaces with different depths

- Processing at a distance from the material

- Possible integration with wider manufacturing processes

Find out the OT-LAS technology for galvanometer laser systems.

OT-LAS has developed galvanometer laser systems with extraordinary performance. Due to in-house design and proprietary technology we have developed very high-profile components to further streamline processing, ranging from quality scanning heads, with the most powerful laser sources in the market, to excellent optical systems as well as extraordinarily versatile and user-friendly management software. All of this is totally made in Italy, with proprietary technology by the EL.EN group including OT-LAS.

Find out our laser machines on the Ot-LAS website.