It is very important to set the power for marking or cutting by CO2 laser, to obtain high-quality processing. Choosing an optical head that correctly deflects the laser beam to the material to be treated is also essential. These parameters affect the process speed, accuracy and protection of the material used. Furthermore, knowing the ideal processing powers for laser cutting and marking allows consciously choosing the most suitable laser system for your company production. How can you understand what laser power, optical head and resolutions are required based on your goals?

What do you mean by laser power?

Before getting into the matter of choosing the ideal laser power for each type of processing, let us define what this parameter exactly means. The power of a CO2 laser is specified in watts, and indicates the quantity of luminous energy emitted by the laser source. Once the desired power has been chosen, this can be easily set through the laser machine software. Even more important is considering the power density, namely the power value by unit area, which is given by Π R2 (where R is the radius of the laser spot). The lower the laser spot, the higher the density power and the process efficiency.

What do you mean by optical head of a laser system?

There are two methods to manage a laser beam, by focusing and deflecting it to the material to be processed:

- with focusing and mechanical handling optical head

- with polar galvanometer scanning optical head

In the first case, the laser beam is focused and has a reduced-size spot, with a focusing lens that concentrates all the energy to a small portion. Handling of the optical head is mechanical, not particularly fast, and subject to the loss of focus and efficiency when moving away, even slightly, from the focus position. Such optical system is used in the Cartesian cutting machines, with exclusively mechanical handling of the beam. In the second case, the beam is focused by a multiple-optics lens, and handled by high-reflectivity mirrors. The movement is controlled by extremely precise and fast galvanometers, with performances 8-10 times higher compared to the mechanical handling.

How to understand the laser power required for cutting and engraving?

The value of ideal power and power density for a certain type of processing changes depending on several factors, including the maximum power allowed by the laser machine. In fact, different laser systems guarantee different efficiency, both regarding performances in terms of power and speed, and in terms of quality of the sources and optical system. To determine which power to set through the software, it is very important to consider all aspects of the processing, in particular:

Type of material

The CO2 laser is suitable for cutting and marking a wide range of synthetic and natural materials. Depending on the type of materials, some can be marked and cut, while others can only be marked. Each material requires different levels of power to obtain optimum processing based on the result you want to obtain, on the productivity and quality. These aspects contribute to offering the best result only if available and conveniently adjusted in the laser machine in use. Generally, the higher the power, the higher the processing speed and the better the processing quality, with lesser browning of the material. In any case, the laser beam leaves heat on the material, therefore when cutting and marking the track will always have a browning effect. Most of all for laser cutting, it will then be necessary to clean or protect the material before starting the processing.

Material thickness

To obtain a cut with clean and sharp edges, it is necessary to consider the thickness of the material to be processed. Using too low power for the thickness required may prevent from obtaining the desired result or require many steps to reach it. The result would be a production slowdown which would affect the corporate costs. Therefore, before choosing a CO2 laser machine you should assess the thickness of the materials to be processed, and whether the goal is cutting or marking.

Type of laser processing

Cutting and engraving by CO2 laser require different power levels. With the same thickness and material quality, cutting requires higher power than engraving and marking. If the CO2 laser machine is headed for both types of processing, it is important to choose a machine that can guarantee a suitable cutting power.

Productivity and speed required

The processing power affects the process speed. A high power can speed up cutting and engraving of the material, by increasing the company productivity. However, the type of material in question is always to be considered in order to set a suitable power that guarantees a high-quality result.

How to choose the power of the laser machine: conclusions

As mentioned, the ideal processing power depends on several factors that contribute to the final result. The type of material to be processed, its thickness, the type of processing and production speed are essential aspects when calculating a suitable power. For this reason, when buying a laser machine, it is important to rely on trustworthy manufacturers that are available to provide all the information required, and recommend the best model based on your company’s needs. At the same time, it is important to count on laser systems equipped with high-precision optical head, without which the machine power would become inefficient.

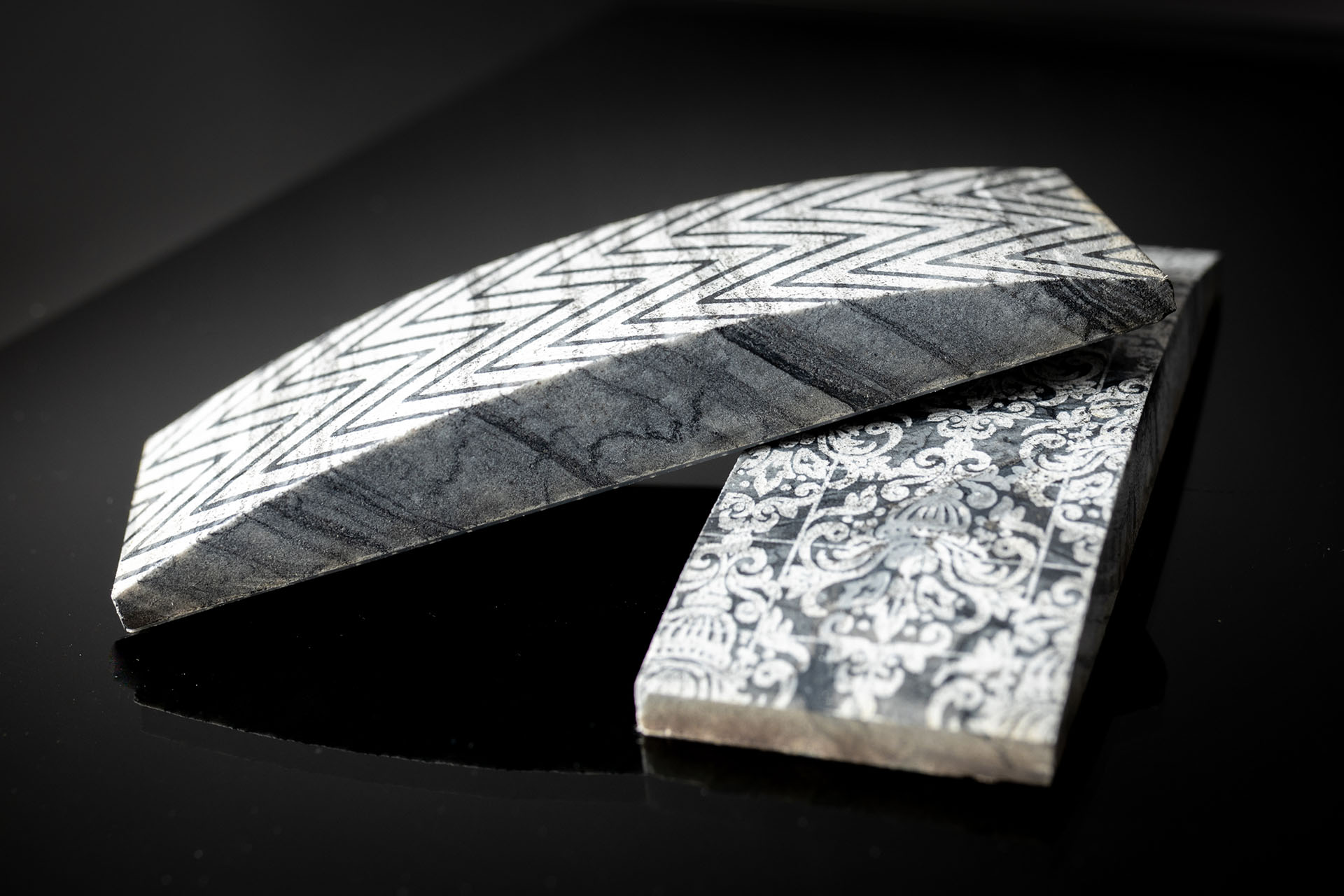

OT-LAS laser machines for any type of material

OT-LAS CO2 laser systems are designed to guarantee the best performances in terms of quality, power, and speed over a wide range of materials. From organic materials, such as leather, wood, and natural fibres, up to the synthetic ones, such as plastic and technical fabrics, OT-LAS laser machines offer elegant and flexible processing results. The proprietary technology guarantees the quality of Made-in-Italy machinery, with custom-made configurations and qualified assistance. The ultrahigh definition optical system and innovative software allow processing with pinpoint accuracy, even on large formats.

Find out the laser machine that best meets your needs with the OT-LAS automatic configurator.