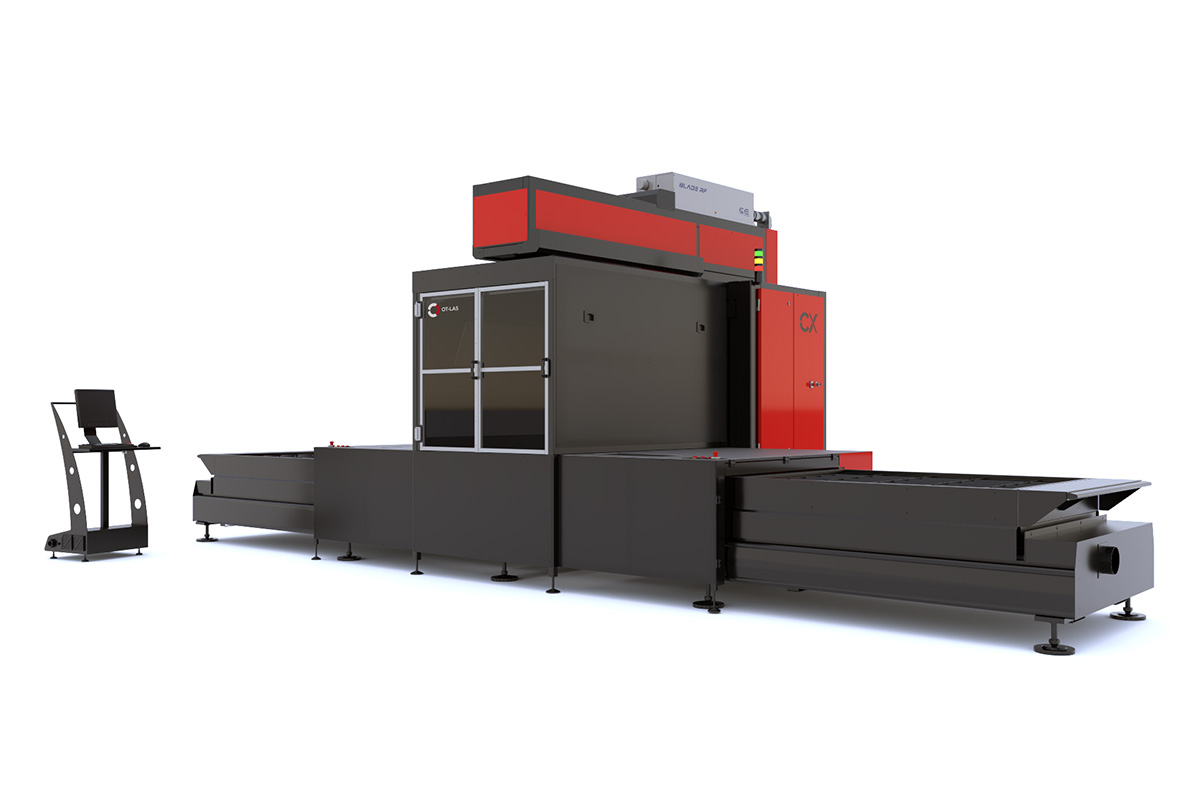

CX, the laser cutting and marking machine for large areas

Designed and implemented by taking advantage of our expertise in this sector, CX places itself on the market for the decoration of leather, footwear components and other materials, such as wood.

CX can process the following materials:

- Textile

- Leather

- Marble

- Wood

- Glass

- Ceramic

- Acrylic

- Paper

- Veneering

Advantages of CX laser machine

The CX laser system is built on a compact mechanic structure and can easily be adapted to smaller working environments.

The CX highlights:

- Equipped with graphic and operating software and Corel Draw graphic engine.

- For each work, it is possible to assign geometric and processing parameters and set any drawing repetitions or compositions.

- Great accuracy of laser spot due to the HD scanning head.

- Great flexibility, possibility to process small objects up to 1200×2500mm-size.

CX Double: Non-stop work

The CX Double model allows you to work without downtime thanks to the automatic double bed:

- It allows to optimize the loading and unloading times: while loading the job on one of the two bed, the laser process continues on the other one. In this way, the operational efficiency is kept and maintains perfect continuity in production.

- It allows continuous and step-by-step machining to meet the company’s needs with maximum flexibility in the organization of processes and working times.

Technical characteristics

CX is equipped with a self-refilling radio-frequency laser source (with continuous power up to 1500W), with an ultra-high-definition galvanometric system (with single useful area up to 1200×1200 mm) and a graphic and operating software with Corel Draw graphic engine, which is ideal for the realization of files and for the entire system functioning.

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Single useful area (mm) | from 700×700 to 1200×1200 – Rated spot from 0.35 mm to 0.6mm | ||||

| X-axis automatic movement | Stroke: 1000 mm | ||||

| Y-axis automatic plan | Stroke: 1500 mm Step movement continuous mov. (“fly marking”) | ||||

| Useful marking area (mm) | 700×2200 with single area 700×700 1200×2700 with single area 1200×1200 | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 H refrigerator: 400 3F+T ±10% – 50 Hz | ||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Useful marking area (mm) | from 500×500 to 1000×1000 – Rated spot from 0.25 mm to 0.5 mm from 700×700 to 1200×1200 – Rated spot from 0.35 mm to 0.6mm | ||||

| X-axis automatic movement | Stroke: 1000 mm | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% 50 H refrigerator: 400 3F+T ±10% 50 Hz | ||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Single useful area (mm) | from 600×600 to 1200×1200 – Rated spot from 0.3 mm to 0.6 mm | ||||

| X-axis automatic movement | Stroke: 1000 mm | ||||

| Y-axis automatic plan | Step movement continuous mov. (“fly marking”) | ||||

| Useful marking area (mm) | 1200×1600 | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% 50 H refrigerator: 400 3F+T ±10% 50 Hz | ||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Single useful area (mm) | from 700×700 to 1200×1200 – Rated spot from 0.35 mm to 0.6mm | ||||

| X-axis automatic movement | Stroke: 1000 mm | ||||

| Y-axis automatic plan | Stroke: 1500 mm Step movement continuous mov. (“fly marking”) | ||||

| Useful marking area (mm) | 700×2200 with single area 700×700 1200×2700 with single area 1200×1200 | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 H refrigerator: 400 3F+T ±10% – 50 Hz | ||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Useful marking area (mm) | from 500×500 to 1000×1000 – Rated spot from 0.25 mm to 0.5 mm from 700×700 to 1200×1200 – Rated spot from 0.35 mm to 0.6mm | ||||

| X-axis automatic movement | Stroke: 1000 mm | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 H refrigerator: 400 3F+T ±10% – 50 Hz | ||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Single useful area (mm) | from 600×600 to 1200×1200 – Rated spot from 0.3 mm to 0.6 mm | ||||

| X-axis automatic movement | Stroke: 1000 mm | ||||

| Y-axis automatic plan | Step movement continuous mov. (“fly marking”) | ||||

| Useful marking area (mm) | 1200×1600 | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 H refrigerator: 400 3F+T ±10% – 50 Hz | ||||

Accessories and hardware for CX

Conveyor

System for continuous processing, suitable for different process types.

Roll system

System for the processing from roll to roll for CX.

Vision system

The vision system allows recognizing the shapes of objects positioned on the working table, in combination with Smart Trim software.

Automatic moving table

Automatic moving table with high precision movement and absolute encoder, for continuous or stepped processing.

Automatic double bed

(Model CX Double) Double beds allow the pendulum machining, allowing to load and unload one bed while the other is busy in the processing, for a perfect continuity of operation.

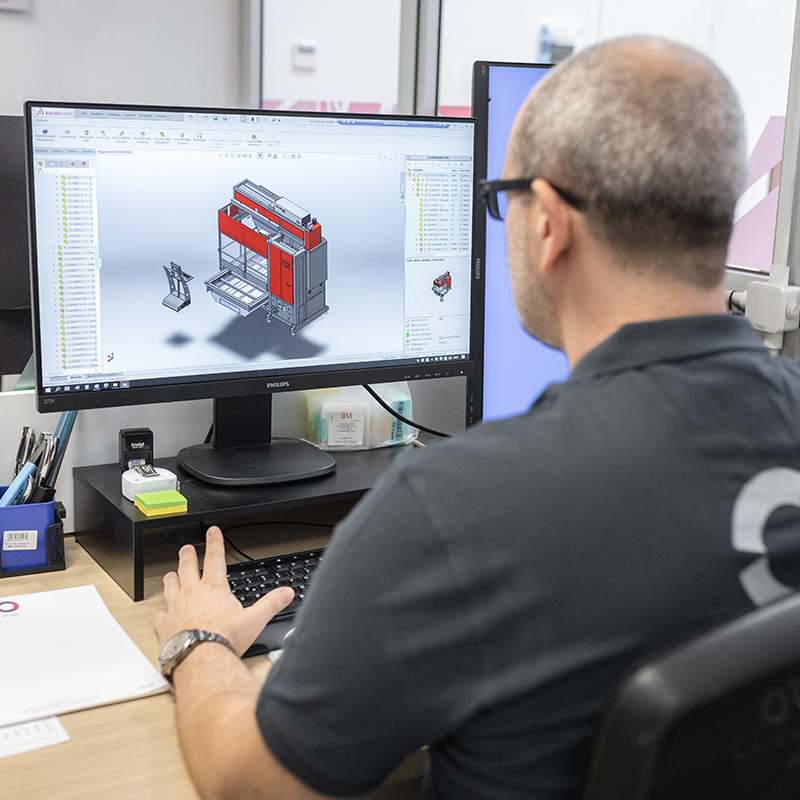

Software for CX

A graphic and operating software with specific Corel Draw graphic engine for the realization of files and for the entire system functioning. For each work, it is possible to assign geometric parameters, processing parameters and set any drawing repetitions or compositions, in case the system is equipped with automatic table.

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.

Software for the recognition of plan surfaces edges. Due to this application, laser processing will be optimized based on the surface requested. Smart Trim is combined with the vision system.